Kubva pamusimboti wekushanda we LEDs, zviri pachena kuti epitaxial wafer material ndiyo yakakosha chikamu che LED. Muchokwadi, makiyi optoelectronic paramita akadai sewavelength, kupenya, uye kumberi voltage zvinonyanya kutsanangurwa neiyo epitaxial zvinhu. Epitaxial wafer tekinoroji nemidziyo yakakosha pakugadzira, neMetal-Organic Chemical Vapor Deposition (MOCVD) iri iyo nzira yekutanga yekukura yakaonda imwe-crystal layers yeIII-V, II-VI makomisheni, uye alloys awo. Pazasi pane mamwe mafambiro emangwana mu LED epitaxial wafer tekinoroji.

1. Kuvandudzwa kweNzvimbo mbiri dzeKukura

Parizvino, kugadzirwa kwekutengesa kunoshandisa nhanho mbiri yekukura, asi huwandu hwema substrates anogona kutakurwa kamwechete ane mashoma. Nepo 6-wafer masisitimu akakura, michina inobata akatenderedza makumi maviri mawafer ichiri kugadzirwa. Kuwedzera huwandu hwewafers kazhinji kunotungamira mukusakwana kufanana muepitaxial layers. Zviitiko zvenguva yemberi zvinotarisa pamativi maviri:

- Kugadzira matekinoroji anobvumira kurodha mamwe ma substrates mukamuri imwe chete yekuita, zvichiita kuti ive yakakodzera kugadzirwa kwakakura uye kuderedza mutengo.

- Kufambira mberi zvakanyanya otomatiki, inodzokororwa imwe-wafer michina.

2. Hydride Vapor Phase Epitaxy (HVPE) Technology

Iyi tekinoroji inogonesa kukurumidza kukura kwemafirimu akakora ane yakaderera dislocation density, iyo inogona kushanda se substrates yehomoepitaxial kukura uchishandisa dzimwe nzira. Pamusoro pezvo, mafirimu eGaN akaparadzaniswa kubva kune substrate anogona kuve dzimwe nzira dzeakawanda GaN single-crystal chips. Nekudaro, HVPE ine zvimhingamipinyi, senge kuomerwa mukunyatso kudzora ukobvu uye corrosive reaction magasi anotadzisa imwe kuvandudzwa mukuchena kwezvinhu zveGaN.

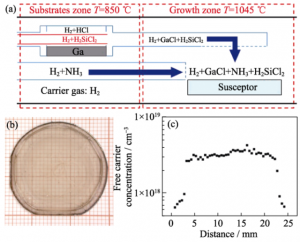

Si-doped HVPE-GaN

(a) Chimiro cheSi-doped HVPE-GaN reactor; (b) Mufananidzo we800 μm- gobvu Si-doped HVPE-GaN;

(c) Kugovera kwemahara mutakuri wevasungwa pamwe nedhayamita yeSi-doped HVPE-GaN

3. Selective Epitaxial Growth kana Lateral Epitaxial Growth Technology

Iyi nzira inogona kuwedzera kuderedza dislocation density uye kugadzirisa crystal quality yeGaN epitaxial layers. Iyo nzira inosanganisira:

- Kuisa GaN layer pane yakakodzera substrate (safire kana SiC).

- Kuisa polycrystalline SiO₂ mask layer pamusoro.

- Kushandisa photolithography uye etching kugadzira GaN windows uye SiO₂ mask mitsetse.Munguva yekukura kunotevera, GaN inotanga kukura yakatwasuka mumahwindo uye yozotevera padivi peSiO₂ mitsetse.

XKH's GaN-on-Sapphire wafer

4. Pendeo-Epitaxy Technology

Iyi nzira inoderedza zvakanyanya kukanganisa kwelattice kunokonzerwa nelattice uye kupisa kusawirirana pakati pe substrate uye epitaxial layer, zvichiwedzera kuwedzera GaN crystal quality. Matanho acho anosanganisira:

- Kukura GaN epitaxial layer pane yakakodzera substrate (6H-SiC kana Si) uchishandisa nhanho mbiri.

- Kuita yakasarudzika etching ye epitaxial layer kusvika kune substrate, kugadzira alternating mbiru (GaN/buffer/substrate) uye migero zvimiro.

- Kukura mamwe maGaN layers, ayo anotambanuka kubva padivi pembiru dzeGaN dzekutanga, akaturikwa pamusoro pemigero.Sezvo pasina mask inoshandiswa, izvi zvinodzivirira kusangana pakati peGaN uye mask zvinhu.

XKH's GaN-on-Silicon wafer

5. Kuvandudzwa kwePfupi-Wavelength UV LED Epitaxial Materials

Izvi zvinoisa hwaro hwakasimba hweUV-inofadza phosphor-based white LEDs. Mazhinji maphosphor akakwira-anoshanda anogona kunakidzwa nemwenje weUV, ichipa yakanyanya kupenya kupenya kupfuura yazvino YAG: Ce system, nekudaro ichisimudzira chena LED kuita.

6. Multi-Quantum Well (MQW) Chip Technology

Muzvimiro zveMQW, tsvina dzakasiyana dzinoitwa panguva yekukura kwechiedza-emitting layer kugadzira akasiyana matsime ehuwandu. Kubatanidzwazve kwemafotoni anoburitswa kubva mumatsime aya kunoburitsa chiedza chichena zvakananga. Iyi nzira inonatsiridza hunyanzvi hwekuita, inoderedza mitengo, uye inorerutsa kurongedza uye kutonga kwedunhu, kunyangwe ichipa matambudziko makuru ehunyanzvi.

7. Kuvandudzwa kwe "Photon Recycling" Technology

Muna Ndira 1999, Sumitomo yekuJapan yakagadzira mwenje chena uchishandisa ZnSe zvinhu. Iyo tekinoroji inosanganisira kukura CdZnSe yakaonda firimu paZnSe single-crystal substrate. Kana yaiswa magetsi, bhaisikopo rinoburitsa mwenje weblue, uyo unodyidzana neZnSe substrate kuti ibudise mwenje yeyero inopindirana, zvichikonzera chiedza chichena. Saizvozvo, Boston University's Photonics Research Center yakarongedza AlInGaP semiconductor komisheni pane yebhuruu GaN-LED kugadzira mwenje chena.

8. LED Epitaxial Wafer Process Flow

① Epitaxial Wafer Fabrication:

Substrate → Magadzirirwo ezvivakwa → Buffer layer kukura → N-mhando yeGaN layer kukura → MQW light-emitting layer kukura → P-mhando GaN layer kukura → Annealing → Kuedza (photoluminescence, X-ray) → Epitaxial wafer

② Chip Kugadzirwa:

Epitaxial wafer → Mask design nekugadzira → Photolithography → Ion etching → N-mhando electrode (deposition, annealing, etching) → P-mhando electrode (deposition, annealing, etching) → Dicing → Chip kuongorora uye grading.

ZMSH's GaN-on-SiC wafer

Nguva yekutumira: Jul-25-2025