SiC wafer's abstract

Silicon carbide (SiC) zvimeduyave iyo substrate yesarudzo yepamusoro-simba, yakakwirira-frequency, uye yepamusoro-tembiricha yemagetsi mukati memotokari, simba rinogoneka, uye nzvimbo dzemuchadenga. Yedu portfolio inovhara makiyi polytypes uye doping zvirongwa — nitrogen-doped 4H (4H-N), yakakwirira-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), uye p-mhando 4H/6H (4H/6H-P)—inopihwa mumakiredhi matatu emhando: PRIME (yakakwenenzverwa, yakakwenenzverwa, isina kucheneswa DUMMY) ONGORORO (custom epi layers uye doping profiles yeR&D). Wafer madhayamita akareba 2 ″, 4 ″, 6 ″, 8 ″, uye 12 ″ kuti aenderane ese maturusi enhaka uye machira epamusoro. Isu tinopawo monocrystalline boules uye yakanyatso tariswa mhodzi makristasi kutsigira-mumba makristasi kukura.

Yedu 4H-N wafers inoratidzira inotakura densities kubva 1 × 10¹⁶ kusvika 1 × 10¹⁹ cm⁻³ uye resistivities ye 0.01–10 Ω·cm, inounza yakanakisa kufamba kweelectron uye minda yekuputsika pamusoro pe2 MV/cm-yakanakira Schottky diode, uye JOSsFET diode. HPSI substrates inodarika 1×10¹² Ω·cm resistivity ine micropipe densities pazasi 0.1 cm⁻², kuve nechokwadi chekuvuza kushoma kweRF uye microwave zvishandiso. Cubic 3C-N, inowanikwa mu 2 ″ uye 4 ″ mafomati, inogonesa heteroepitaxy pasilicon uye inotsigira novel photonic uye MEMS application. P-mhando 4H/6H-P mawafer, akaiswa aruminiyamu kusvika 1×10¹⁶–5×10¹⁸ cm⁻³, anofambisa dhizaini yekuvaka.

SiC wafer, PRIME wafers anoiswa kemikari-mechanicha yekupukuta kusvika <0.2 nm RMS pamusoro roughness, yakazara ukobvu kusiyana pasi pe3 µm, uye uta <10 µm. DUMMY substrates inomhanyisa kusangana uye kurongedza bvunzo, nepo RESEARCH wafers inoratidzira epi-layer ukobvu hwe2-30 µm uye bespoke doping. Zvese zvigadzirwa zvinopupurirwa neX-ray diffraction (rocking curve <30 arcsec) uye Raman spectroscopy, ine magetsi ebvunzo-Hall zviyero, C-V profiling, uye micropipe scanning-inoona JEDEC neSEMI kutevedzera.

Maboules anosvika 150 mm dhayamita anokura kuburikidza nePVT uye CVD ine dislocation densities pazasi 1 × 10³ cm⁻² uye yakaderera micropipe kuverenga. Makristasi embeu anochekwa mukati me 0.1° ye-c-axis kuti avimbise kukura kunoberekana uye negoho rekucheka.

Nekubatanidza akawanda mapolytypes, doping akasiyana, emhando yemagiredhi, SiC wafer saizi, uye-mumba boule uye mhodzi-crystal kugadzirwa, yedu SiC substrate chikuva inofambisa macheni ekugovera uye inomhanyisa kugadzirwa kwechishandiso chemotokari dzemagetsi, smart grid, uye hutsinye-zvakatipoteredza zvikumbiro.

SiC wafer's abstract

Silicon carbide (SiC) zvimeduyave iyo SiC substrate yesarudzo yemhando yepamusoro-simba, yakakwirira-frequency, uye yakakwirira-tembiricha yemagetsi mukati memotokari, simba rinogoneka, uye nzvimbo dzemuchadenga. Yedu portfolio inovhara makiyi polytypes uye doping zvirongwa-nitrogen-doped 4H (4H-N), yakakwirira-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), uye p-mhando 4H/6H (4H/6H-P)-inopihwa mumagiredhi matatu emhando:SiC wafer.PRIME (yakanyatsokwenenzverwa, giredhi-giredhi substrates), DUMMY (yakaputirwa kana isina kupepereswa kuti iedze maitiro), uye RESEARCH (custom epi layers uye doping profiles yeR&D). SiC Wafer madhayamita akareba 2 ″, 4 ″, 6 ″, 8 ″, uye 12 ″ kuti ikwane ese maturusi enhaka uye machira epamusoro. Isu tinopawo monocrystalline boules uye yakanyatso tariswa mhodzi makristasi kutsigira-mumba makristasi kukura.

Yedu 4H-N SiC wafers inoratidzira inotakura densities kubva 1 × 10¹⁶ kusvika 1 × 10¹⁹ cm⁻³ uye resistivities ye 0.01-10 Ω·cm, kuendesa yakanakisa kufamba kweelectron uye minda yekuputsika pamusoro pe2 MV/cm-yakanakira Schottky diodes, MOSFETs diodes, uye JFETS. HPSI substrates inodarika 1×10¹² Ω·cm resistivity ine micropipe densities pazasi 0.1 cm⁻², kuve nechokwadi chekuvuza kushoma kweRF uye microwave zvishandiso. Cubic 3C-N, inowanikwa mu 2 ″ uye 4 ″ mafomati, inogonesa heteroepitaxy pasilicon uye inotsigira novel photonic uye MEMS application. SiC wafer P-mhando 4H/6H-P mawaferi, akaiswa aruminiyamu kusvika 1 × 10¹⁶–5×10¹⁸ cm⁻³, fambisa dhizaini yekuvaka.

SiC wafer PRIME wafers anovhenekwa nemakemikari-mechanicha kusvika <0.2 nm RMS kushata kwepamusoro, kusiyana kwehupamhi pasi pe3 µm, uye uta <10 µm. DUMMY substrates inomhanyisa kusangana uye kurongedza bvunzo, nepo RESEARCH wafers inoratidzira epi-layer ukobvu hwe2-30 µm uye bespoke doping. Zvese zvigadzirwa zvinopupurirwa neX-ray diffraction (rocking curve <30 arcsec) uye Raman spectroscopy, ine magetsi ebvunzo-Hall zviyero, C-V profiling, uye micropipe scanning-inoona JEDEC neSEMI kutevedzera.

Maboules anosvika 150 mm dhayamita anokura kuburikidza nePVT uye CVD ine dislocation densities pazasi 1 × 10³ cm⁻² uye yakaderera micropipe kuverenga. Makristasi embeu anochekwa mukati me 0.1° ye-c-axis kuti avimbise kukura kunoberekana uye negoho rekucheka.

Nekubatanidza akawanda mapolytypes, doping akasiyana, emhando yemagiredhi, SiC wafer saizi, uye-mumba boule uye mhodzi-crystal kugadzirwa, yedu SiC substrate chikuva inofambisa macheni ekugovera uye inomhanyisa kugadzirwa kwechishandiso chemotokari dzemagetsi, smart grid, uye hutsinye-zvakatipoteredza zvikumbiro.

6inch 4H-N mhando yeSiC wafer's data sheet

| 6inch SiC wafers data sheet | ||||

| Parameter | Sub-Parameter | Z Grade | P Giredhi | D Giredhi |

| Diameter | 149.5–150.0 mm | 149.5–150.0 mm | 149.5–150.0 mm | |

| Ukobvu | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| Ukobvu | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Wafer Orientation | Kubva paaxis: 4.0 ° yakananga <11-20> ± 0.5 ° (4H-N); Paaxis: <0001> ±0.5° (4H-SI) | Kubva paaxis: 4.0 ° yakananga <11-20> ± 0.5 ° (4H-N); Paaxis: <0001> ±0.5° (4H-SI) | Kubva paaxis: 4.0 ° yakananga <11-20> ± 0.5 ° (4H-N); Paaxis: <0001> ±0.5° (4H-SI) | |

| Micropipe Density | 4H‑N | ≤ 0.2 cm⁻² | ≤ 2cm⁻² | ≤ 15 cm⁻² |

| Micropipe Density | 4H‑SI | ≤ 1cm⁻² | ≤ 5cm⁻² | ≤ 15 cm⁻² |

| Resistivity | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Resistivity | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Yekutanga Flat Oriental | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Primary Flat Length | 4H‑N | 47.5 mm ± 2.0 mm | ||

| Primary Flat Length | 4H‑SI | Notch | ||

| Kusabatanidzwa kumucheto | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Kukasharara | ChiPolish | Ra ≤ 1 nm | ||

| Kukasharara | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Edge Cracks | Hapana | Cumulative kureba ≤ 20 mm, imwe chete ≤ 2 mm | ||

| Hex Plates | Cumulative area ≤ 0.05% | Cumulative area ≤ 0.1% | Yakawedzerwa nzvimbo ≤ 1% | |

| Polytype Nzvimbo | Hapana | Yakawedzerwa nzvimbo ≤ 3% | Yakawedzerwa nzvimbo ≤ 3% | |

| Carbon Inclusions | Cumulative area ≤ 0.05% | Yakawedzerwa nzvimbo ≤ 3% | ||

| Surface Scratches | Hapana | Hurefu hwekuwedzera ≤ 1 × wafer dhayamita | ||

| Edge Chips | Hapana anotenderwa ≥ 0.2 mm hupamhi & kudzika | Kusvika ku7 machipisi, ≤ 1 mm imwe neimwe | ||

| TSD (Threading Screw Dislocation) | ≤ 500 cm⁻² | N/A | ||

| BPD (Base Plane Dislocation) | ≤ 1000 cm⁻² | N/A | ||

| Surface Kusvibiswa | Hapana | |||

| Packaging | Multi-wafer cassette kana single wafer container | Multi-wafer cassette kana single wafer container | Multi-wafer cassette kana single wafer container | |

4inch 4H-N mhando yeSiC wafer's data sheet

| 4inch SiC wafer's data sheet | |||

| Parameter | Zero MPD Kugadzirwa | Standard Production Giredhi (P Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 99.5 mm–100.0 mm | ||

| Hukobvu (4H-N) | 350µm±15µm | 350µm±25µm | |

| Hukobvu (4H-Si) | 500 µm±15µm | 500µm±25µm | |

| Wafer Orientation | Off axis: 4.0 ° yakananga <1120> ± 0.5 ° ye4H-N; Paaxis: <0001> ± 0.5 ° ye4H-Si | ||

| Micropipe Density (4H-N) | ≤0.2 masendimita⁻² | ≤2 masendimita⁻² | ≤15 cm⁻² |

| Micropipe Density (4H-Si) | ≤1 cm⁻² | ≤5 masendimita⁻² | ≤15 cm⁻² |

| Kuramba (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Resistivity (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Yekutanga Flat Oriental | [10-10] ±5.0° | ||

| Primary Flat Length | 32.5 mm ±2.0 mm | ||

| Secondary Flat Length | 18.0 mm ±2.0 mm | ||

| Secondary Flat Orientation | Silicon yakatarisana kumusoro: 90 ° CW kubva kune yekutanga flat ± 5.0 ° | ||

| Kusabatanidzwa kumucheto | 3 mm | ||

| LTV/TTV/Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Kukasharara | Polish Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Edge Cracks By High Intensity Chiedza | Hapana | Hapana | Cumulative kureba ≤10 mm; kureba kamwe ≤2 mm |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤0.05% | Cumulative area ≤0.05% | Cumulative area ≤0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Hapana | Yakawedzerwa nzvimbo ≤3% | |

| Visual Carbon Inclusions | Cumulative area ≤0.05% | Yakawedzerwa nzvimbo ≤3% | |

| Silicon Surface Scratches By High Intensity Chiedza | Hapana | Hurefu hwekuwedzera ≤1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥0.2 mm hupamhi nekudzika | 5 inotenderwa, ≤1 mm imwe neimwe | |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | Hapana | ||

| Threading screw dislocation | ≤500 cm⁻² | N/A | |

| Packaging | Multi-wafer cassette kana single wafer container | Multi-wafer cassette kana single wafer container | Multi-wafer cassette kana single wafer container |

4inch HPSI mhando yeSiC wafer's data sheet

| 4inch HPSI mhando yeSiC wafer's data sheet | |||

| Parameter | Zero MPD Yekugadzira Giredhi (Z Giredhi) | Standard Production Giredhi (P Giredhi) | Dummy Giredhi (D giredhi) |

| Diameter | 99.5–100.0 mm | ||

| Hukobvu (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| Wafer Orientation | Off axis: 4.0 ° yakananga <11-20> ± 0.5 ° ye4H-N; Paaxis: <0001> ± 0.5 ° ye4H-Si | ||

| Micropipe Density (4H-Si) | ≤1 cm⁻² | ≤5 masendimita⁻² | ≤15 cm⁻² |

| Resistivity (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Yekutanga Flat Oriental | (10-10) ±5.0° | ||

| Primary Flat Length | 32.5 mm ±2.0 mm | ||

| Secondary Flat Length | 18.0 mm ±2.0 mm | ||

| Secondary Flat Orientation | Silicon yakatarisana kumusoro: 90 ° CW kubva kune yekutanga flat ± 5.0 ° | ||

| Kusabatanidzwa kumucheto | 3 mm | ||

| LTV/TTV/Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Hushasha (C face) | ChiPolish | Ra ≤1 nm | |

| Hukasha (Si face) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Edge Cracks By High Intensity Chiedza | Hapana | Cumulative kureba ≤10 mm; kureba kamwe ≤2 mm | |

| Hex Plates By High Intensity Chiedza | Cumulative area ≤0.05% | Cumulative area ≤0.05% | Cumulative area ≤0.1% |

| Polytype Nzvimbo NeKusimba Kwakanyanya Chiedza | Hapana | Yakawedzerwa nzvimbo ≤3% | |

| Visual Carbon Inclusions | Cumulative area ≤0.05% | Yakawedzerwa nzvimbo ≤3% | |

| Silicon Surface Scratches By High Intensity Chiedza | Hapana | Hurefu hwekuwedzera ≤1 wafer dhayamita | |

| Edge Chips By High Intensity Chiedza | Hapana anotenderwa ≥0.2 mm hupamhi nekudzika | 5 inotenderwa, ≤1 mm imwe neimwe | |

| Silicon Surface Kusvibiswa NeKunyanya Kusimba Chiedza | Hapana | Hapana | |

| Threading Screw Dislocation | ≤500 cm⁻² | N/A | |

| Packaging | Multi-wafer cassette kana single wafer container | ||

SiC wafer's application

-

SiC Wafer Power Modules yeEV Inverters

SiC wafer-based MOSFETs uye madhiodhi akavakirwa pamhando yepamusoro SiC wafer substrates anoburitsa kurasikirwa kwekupedzisira-kuderera kwekuchinja. Nekushandisa tekinoroji yeSiC wafer, aya emagetsi mamodule anoshanda pakakwirira voltages uye tembiricha, zvichiita kuti iwedzere kushanda zvakanaka traction inverters. Kubatanidza SiC wafer inofa mumatanho emagetsi kunoderedza kutonhora zvinodiwa uye tsoka, kuratidza kugona kwakazara kweSiC wafer innovation. -

Yakakwira-Frequency RF & 5G Zvishandiso paSiC Wafer

RF amplifiers uye ma switch akagadzirwa pane semi-insulating SiC wafer mapuratifomu anoratidza yepamusoro yekupisa conductivity uye kuparara kwemagetsi. SiC wafer substrate inoderedza kurasikirwa kwedielectric paGHz frequencies, nepo SiC wafer's material simba inobvumira kushanda kwakadzikama pasi pesimba repamusoro-soro, high-temperature mamiriro - zvichiita kuti SiC wafer iyo substrate yesarudzo kune inotevera-gen 5G base zviteshi uye radar masisitimu. -

Optoelectronic & LED Substrates kubva kuSiC Wafer

Bhuruu uye UV maLED akakura paSiC wafer substrates anobatsirwa kubva kune yakanakisa reti yekuenzanisa uye kupisa kupisa. Kushandisa yakakwenenzverwa C-face SiC wafer inovimbisa yunifomu epitaxial layer, nepo kuomarara kweSiC wafer kunogonesa wafer kutetepa uye yakavimbika mudziyo kurongedza. Izvi zvinoita kuti SiC wafer iyo yekuenda-kupuratifomu kune yakakwirira-simba, yehupenyu hurefu hwe LED application.

SiC wafer's Q&A

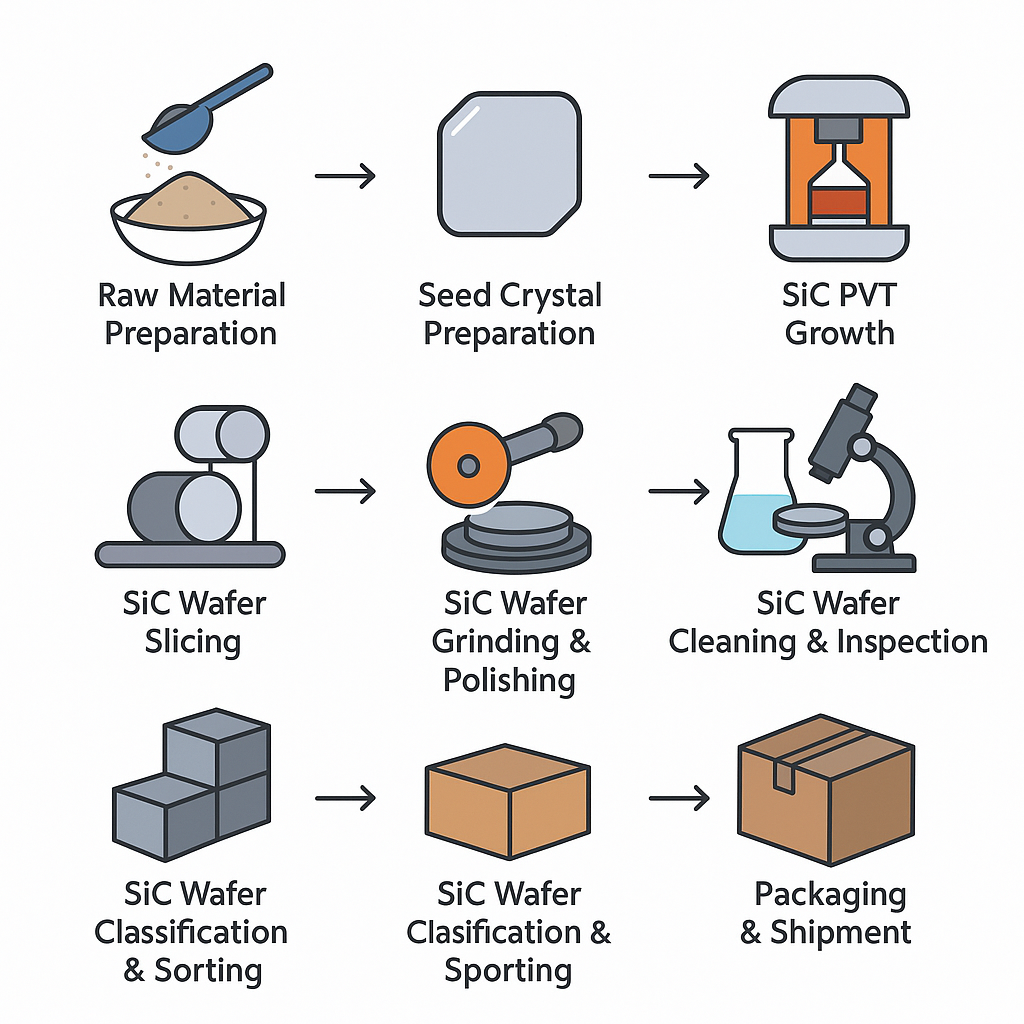

1. Q: SiC wafers anogadzirwa sei?

A:

SiC wafers yakagadzirwaDetailed Matanho

-

SiC wafersRaw Material Gadziriro

- Shandisa ≥5N-grade SiC powder (kusvibiswa ≤1 ppm).

- Sefa uye kufanobika kuti ubvise zvakasara kabhoni kana nitrogen makomisheni.

-

SiCMbeu Crystal Kugadzirira

-

Tora chidimbu che4H-SiC imwe kristaro, cheka parutivi 〈0001〉 kutarisisa kune ~ 10 × 10 mm².

-

Precision polish kuRa ≤0.1 nm uye maka kristaro kutaridzika.

-

-

SiCPVT Kukura (Physical Vapor Transport)

-

Rodha graphite crucible: pasi neSiC hupfu, pamusoro nekristaro yembeu.

-

Enda ku10⁻³–10⁻⁵ Torr kana kudzosera kumashure nehelium yekuchena kwepamusoro pa1 atm.

-

Heat source zone kusvika 2100–2300 ℃, chengetedza nzvimbo yembeu 100–150 ℃ inotonhorera.

-

Dzora chiyero chekukura pa1-5 mm / h kuti uenzanise kunaka uye kubuda.

-

-

SiCIngot Annealing

-

Anneal iyo yakura SiC ingot pa1600–1800 ℃ kwemaawa mana-8.

-

Chinangwa: kubvisa kushushikana kwekushisa uye kuderedza dislocation density.

-

-

SiCWafer Slicing

-

Shandisa saha yewaya yedhaimani kucheka ingot kuita 0.5–1 mm dzakakora mawafer.

-

Deredza kuzunguzika uye lateral simba kudzivirira micro-kutsemuka.

-

-

SiCWaferKukuya & kupukuta

-

Kukuyakubvisa kukuvara kwesawing (hukasha ~10–30 µm).

-

Kukuya zvakanakakuwana flatness ≤5 µm.

-

Chemical-Mechanical polishing (CMP)kusvika pagirazi-sekupera (Ra ≤0.2 nm).

-

-

SiCWaferKuchenesa & Kuongorora

-

Ultrasonic kuchenesamuPiranha mhinduro (H₂SO₄:H₂O₂), DI mvura, kozoti IPA.

-

XRD/Raman spectroscopykusimbisa polytype (4H, 6H, 3C).

-

Interferometrykuyera flatness (<5 µm) uye kutenderera (<20 µm).

-

Zvina-point probekuedza resistivity (eg HPSI ≥10⁹ Ω·cm).

-

Kuongorora kukanganisapasi pepolarized light microscope uye scratch tester.

-

-

SiCWaferKuronga & Kuronga

-

Ronga wafers ne polytype uye yemagetsi mhando:

-

4H-SiC N-mhando (4H-N): mutakuri wekutarisa 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-mhando (6H-N)

-

Vamwe: 3C-SiC, P-mhando, nezvimwe.

-

-

-

SiCWaferPackaging & Shipment

2. Q: Ndezvipi zvakakosha zveSiC wafers pamusoro pesilicon wafers?

A: Kuenzaniswa nesilicon wafers, SiC wafers inogonesa:

-

Higher voltage kushanda(> 1,200 V) ine yakaderera pa-resistance.

-

Kugadzikana kwekushisa kwepamusoro(> 300 ° C) uye yakagadziridza kutonga kwekushisa.

-

Kukurumidza kushandura kumhanyanekuderera kwekuchinja kurasikirwa, kuderedza system-level kutonhora uye saizi mumagetsi ekushandura.

4. Q: Ndezvipi zvinowanzoitika kukanganisa kunobata SiC wafer goho uye kushanda?

A: Hurema hwekutanga muSiC wafers hunosanganisira micropipes, basal plane dislocations (BPDs), uye kukwenya kwepamusoro. Maikoropipi anogona kukonzera njodzi kutadza kwemudziyo; BPDs inowedzera pa-resistance nekufamba kwenguva; uye kukwenya kwepamusoro kunotungamirira kukupwanyika kwewafer kana kusakura kwe epitaxial. Kuongorora kwakasimba uye kudzikisira kukanganisa kwakakosha kuti uwedzere goho reSiC wafer.

Nguva yekutumira: Jun-30-2025