Kucheneswa kwemvura (Wet Clean) ndeimwe yenhanho dzakakosha mumasemiconductor ekugadzira maitiro, ane chinangwa chekubvisa zvakasvibiswa zvakasiyana kubva pamusoro pechifukidzo kuti ive nechokwadi chekuti nhanho dzinotevera dzinogona kuitwa panzvimbo yakachena.

Sezvo saizi yemidziyo yesemiconductor ichiramba ichidzikira uye kunyatsoita zvinodiwa zvichiwedzera, izvo zvinodiwa zvehunyanzvi zvekuchenesa wafer maitiro zvave kuwedzera kuomarara. Kunyangwe zvidiki zvidiki, organic zvinhu, simbi ions, kana oxide zvisaririra pawafer pamusoro zvinogona kukanganisa zvakanyanya kushanda kwechishandiso, zvichikanganisa goho uye kuvimbika kwemidziyo yesemiconductor.

Core Nheyo dzeWafer Kuchenesa

Mwoyo wekuchenesa wafer uri mukubvisa zvinosvibisa zvakasiyana kubva pawafer pamusoro kuburikidza nemuviri, kemikari, uye dzimwe nzira dzekuona kuti wafer ine nzvimbo yakachena yakakodzera kunotevera kugadziriswa.

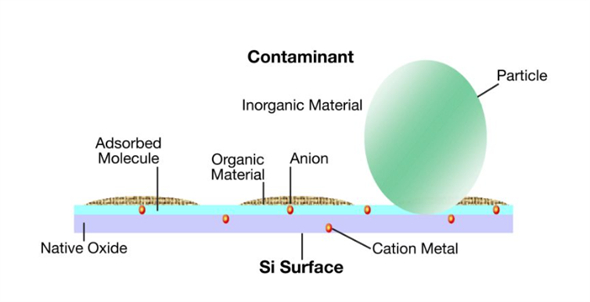

Type of Contamination

Mhedzisiro Huru paChishandiso Chimiro

| chinyorwa Kusvibiswa | Patani kukanganisa

Ion implantation defects

Insulating firimu kuparara kukanganisa

| |

| Metallic Kusvibiswa | Alkali Metals | MOS transistor kusagadzikana

Gedhi oxide firimu kuputsika/kushatisa

|

| Heavy Metals | Yakawedzera PN junction reverse leakage ikozvino

Gedhi oxide firimu kuparara kukanganisa

Minority carrier lifetime degradation

Oxide excitation layer defect generation

| |

| Kusvibiswa Kwemakemikari | Organic Material | Gedhi oxide firimu kuparara kukanganisa

CVD mafirimu akasiyana (nguva dzekufukidzira)

Thermal oxide firimu ukobvu kusiyana (yakawedzera oxidation)

Haze kuitika (wafer, lenzi, girazi, mask, reticle)

|

| Inorganic Dopants (B, P) | MOS transistor Vth inochinja

Si substrate uye yakakwirira kupikisa poly-silicon sheet resistance kusiyana

| |

| Inorganic Bases (amines, ammonia) uye Acids (SOx) | Kuderedzwa kwekugadziriswa kwemakemikari akawedzera kupikisa

Kuitika kwekusvibiswa kwechidimbu uye upfu nekuda kwekugadzirwa kwemunyu

| |

| Native uye Chemical Oxide Mafirimu Nekuda Kwehunyoro, Mhepo | Kuwedzera kuonana kuramba

Gedhi oxide firimu kuputsika/kushatisa

| |

Kunyanya, zvinangwa zvewafer yekuchenesa maitiro zvinosanganisira:

Particle Removal: Kushandisa nzira dzemuviri kana dzemakemikari kubvisa zvimedu zvidiki zvakanamirwa kune wafer pamusoro. Zvimedu zvidiki zvakanyanya kunetsa kubvisa nekuda kwesimba rakasimba remagetsi pakati pawo newafer surface, inoda kurapwa kwakakosha.

Organic Material Removal: Organic zvinosvibisa segirisi uye photoresist masara anogona kunamatira kune wafer pamusoro. Izvi zvinosvibisa zvinowanzo bviswa uchishandisa yakasimba oxidizing agents kana zvinonyungudutsa.

Metal Ion Removal: Metal ion masara pane wafer pamusoro anogona kukanganisa kushanda kwemagetsi uye kunyange kukanganisa anotevera ekugadzirisa matanho. Naizvozvo, chaiwo makemikari mhinduro anoshandiswa kubvisa aya maion.

Oxide Removal: Mamwe maitiro anoda kuti wafer pamusoro ive isina oxide layer, senge silicon oxide. Mumamiriro ezvinhu akadaro, masikirwo oxide layers anofanirwa kubviswa panguva yemamwe matanho ekuchenesa.

Dambudziko rekugadzira tekinoroji yekuchenesa tekinoroji riri mukubvisa zvinosvibisa pasina kukanganisa nzvimbo yewafer, sekudzivirira kuomarara kwepasi, kuora, kana kumwe kukuvara kwemuviri.

2. Wafer Cleaning Process Flow

Iyo wafer yekuchenesa maitiro inowanzo sanganisira akawanda matanho ekuona kubviswa kwakazara kwezvinosvibisa uye kuwana nzvimbo yakachena yakazara.

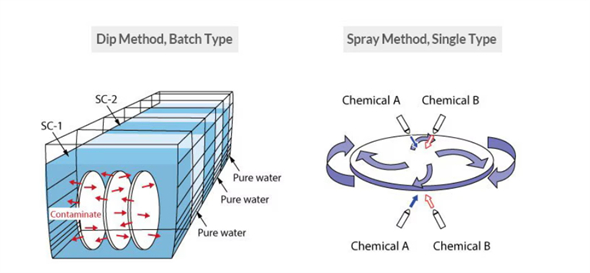

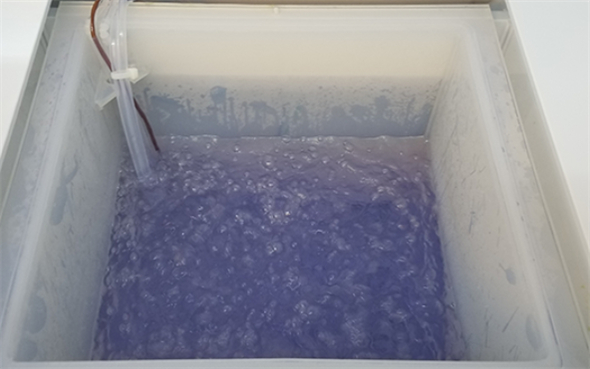

Mufananidzo: Kuenzanisa Pakati peBatch-Type uye Single-Wafer Kuchenesa

Yakajairika wafer yekuchenesa maitiro inosanganisira anotevera matanho makuru:

1. Pre-Cleaning (Pre-Clean)

Chinangwa chekuchenesa kusati kwaitwa kubvisa tsvina yakasununguka uye zvidimbu zvakakura kubva panzvimbo yakasvibirira, iyo inowanikwa kuburikidza nemvura yakasvibiswa (DI Mvura) yekuchenesa uye ultrasonic kuchenesa. Mvura yakasvibiswa inogona kutanga kubvisa zvimedu uye tsvina yakanyungudutswa kubva pamucheka wepamusoro, nepo ultrasonic kuchenesa inoshandisa cavitation madhara kuputsa chisungo pakati pezvimedu nepamusoro pemvura, zvichiita kuti zvive nyore kubvisa.

2. Kuchenesa Kemikari

Kemikari yekuchenesa ndeimwe yematanho epakati muwafer yekuchenesa maitiro, uchishandisa kemikari mhinduro kubvisa organic zvinhu, simbi ions, uye okisidhi kubva pawafer pamusoro.

Organic Material Removal: Kazhinji, acetone kana ammonia/peroxide musanganiswa (SC-1) inoshandiswa kunyungudutsa uye oxidize organic tsvina. Iyo yakajairika reshiyo yeSC-1 mhinduro ndeye NH₄OH

₂O₂

₂O = 1:1:5, ine tembiricha yekushanda inosvika 20°C.

Metal Ion Removal: Nitric acid kana hydrochloric acid/peroxide misanganiswa (SC-2) inoshandiswa kubvisa ayoni esimbi kubva pane wafer pamusoro. Yakajairika reshiyo yeSC-2 mhinduro iHCl

₂O₂

₂O = 1:1:6, tembiricha yakachengetedzwa pa80°C.

Oxide Removal: Mune mamwe maitiro, kubviswa kweiyo yekuzvarwa oxide layer kubva pawafer surface inodiwa, iyo hydrofluoric acid (HF) mhinduro inoshandiswa. Yakajairika reshiyo yeHF mhinduro iHF

₂O = 1:50, uye inogona kushandiswa pakamuri tembiricha.

3. Kuchena Kwekupedzisira

Mushure mekuchenesa kemikari, mawaferi anowanzo pinda nhanho yekupedzisira yekuchenesa kuti ave nechokwadi chekuti hapana masara emakemikari anoramba ari pamusoro. Kuchenesa kwekupedzisira kunonyanya kushandisa mvura yakasvibiswa kuti inyatsosuka. Pamusoro pezvo, kucheneswa kwemvura yeozone (O₃/H₂O) inoshandiswa kuenderera mberi nekubvisa chero zvakasara zvinosvibisa kubva kune wafer pamusoro.

4. Kuomesa

Iwo akacheneswa wafers anofanirwa kuomeswa nekukasira kudzivirira watermark kana kusungirirwazve kwezvinosvibisa. Nzira dzakajairika dzekuomesa dzinosanganisira spin drying uye nitrogen purging. Iyo yekutanga inobvisa hunyoro kubva pawafer pamusoro nekutenderera nekumhanya kwakanyanya, nepo iyo yekupedzisira ichiona kuoma kwakazara nekufuridza yakaoma nitrogen gasi nepamusoro pewafer pamusoro.

Contaminant

Nzira Yekuchenesa Zita

Kemikari Musanganiswa Tsanangudzo

Makemikari

| Zvimedu | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI mvura | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI mvura | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Metals (kwete mhangura) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI mvura | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI mvura | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Dilute hydrofluoric acid/DI mvura (haizobvisa mhangura) | HF/H2O1:50 | |

| Organics | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI mvura | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide/hydrogen peroxide/DI mvura | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone mumvura de-ionized | O3/H2O Yakagadziridzwa Misanganiswa | |

| Native oxide | DHF | Dilute hydrofluoric acid / DI mvura | HF/H2O 1:100 |

| BHF | Yakavharwa hydrofluoric acid | NH4F/HF/H2O |

3. Common Wafer Cleaning Methods

1. RCA Kuchenesa Nzira

Iyo RCA yekuchenesa nzira ndeimwe yeakanyanya hunyanzvi hwekuchenesa wafer muindasitiri yesemiconductor, yakagadziridzwa neRCA Corporation makore makumi mana apfuura. Iyi nzira inonyanya kushandiswa kubvisa organic tsvina uye simbi ion tsvina uye inogona kupedzwa mumatanho maviri: SC-1 (Standard Clean 1) uye SC-2 (Standard Clean 2).

SC-1 Kuchenesa: Danho iri rinonyanya kushandiswa kubvisa organic zvinosvibisa uye zvidimbu. Mushonga wacho musanganiswa weammonia, hydrogen peroxide, uye mvura, iyo inoumba nhete yesilicon oxide layer pane wafer pamusoro.

SC-2 Kuchenesa: Danho iri rinonyanya kushandiswa kubvisa tsvina yesimbi, uchishandisa musanganiswa wehydrochloric acid, hydrogen peroxide, uye mvura. Inosiya mutsetse wakatetepa pawafer pamusoro kudzivirira kusvibiswa zvakare.

2. Piranha yekuchenesa nzira (Piranha Etch Yakachena)

Iyo Piranha yekuchenesa nzira inyanzvi inoshanda kwazvo yekubvisa organic zvinhu, uchishandisa musanganiswa we sulfuric acid nehydrogen peroxide, kazhinji muchiyero che3: 1 kana 4: 1. Nekuda kweiyo yakanyanya kusimba oxidative zvimiro zvemhinduro iyi, inogona kubvisa huwandu hukuru hwe organic zvinhu uye zvakasindimara zvinosvibisa. Iyi nzira inoda kudzora kwakasimba kwemamiriro, kunyanya maererano nekushisa uye kuisa pfungwa, kudzivirira kukuvadza wafer.

Ultrasonic kuchenesa inoshandisa cavitation effect inogadzirwa ne-high-frequency sound waves mumvura kuti ibvise kusvibiswa kubva kune wafer surface. Kuenzaniswa neyechinyakare ultrasonic kuchenesa, megasonic yekuchenesa inoshanda pamwero wepamusoro, ichigonesa kubviswa kwakanyatsoita kwe sub-micron-saizi zvimedu pasina kukonzera kukuvadza kune wafer pamusoro.

4. Ozone Kuchenesa

Ozone yekuchenesa tekinoroji inoshandisa iyo yakasimba oxidizing zvimiro zveozone kuora uye kubvisa organic zvinosvibisa kubva pawafer pamusoro, zvichizozvishandura kuita isingakuvadzi kabhoni dhaikisaidhi nemvura. Iyi nzira haidi kushandiswa kweanodhura makemikari reagents uye inokonzera kushoma kusvibiswa kwezvakatipoteredza, zvichiita kuti ive inobuda tekinoroji mumunda wekuchenesa wafer.

4. Wafer Cleaning Process Equipment

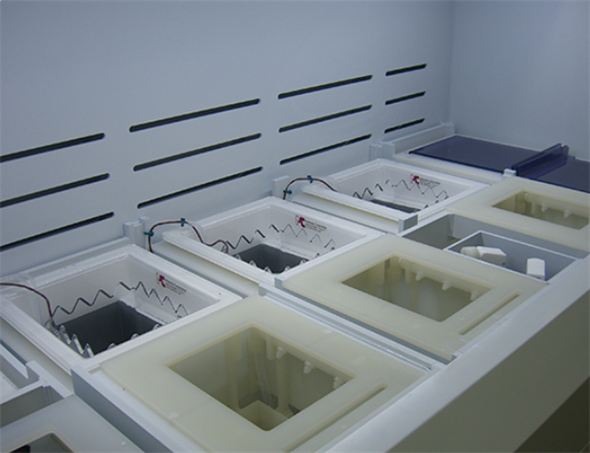

Kuve nechokwadi chekushanda uye kuchengetedzeka kwewafer yekuchenesa maitiro, akasiyana emhando yepamusoro yekuchenesa michina inoshandiswa mukugadzira semiconductor. Mhando huru dzinosanganisira:

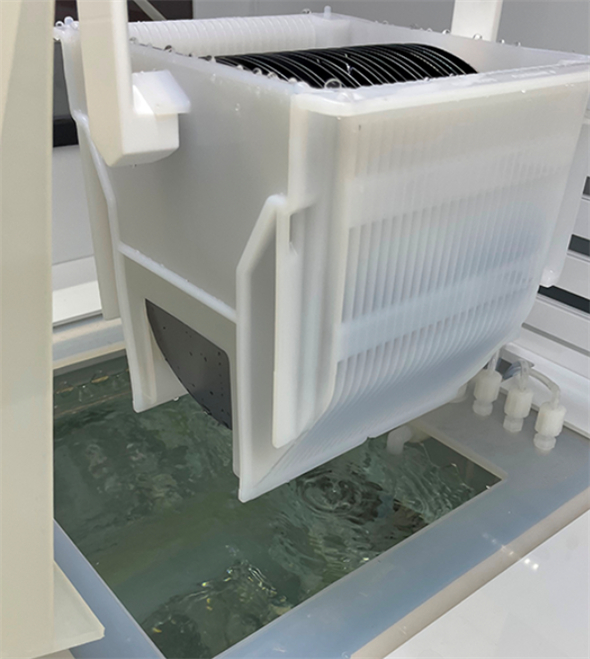

1. Wet Cleaning Equipment

Midziyo yekuchenesa yekunyorova inosanganisira matangi ekunyudza akasiyana, matangi ekuchenesa eultrasonic, uye spin dryers. Midziyo iyi inosanganisa masimba emagetsi uye makemikari reagents kuti abvise zvinosvibisa kubva pane wafer pamusoro. Matangi ekunyudza anowanzo kuve ane tembiricha yekudzora masisitimu kuti ave nechokwadi chekugadzikana uye kushanda kwemakemikari mhinduro.

2. Dry Cleaning Equipment

Dry yekuchenesa michina inonyanya kusanganisira plasma yekuchenesa, iyo inoshandisa yakakwirira-simba zvidimbu muplasma kuita uye kubvisa zvisaririra kubva pawafer pamusoro. Kucheneswa kweplasma kunonyanya kukodzera maitiro anoda kuchengetedza kutendeseka kwepamusoro pasina kuunza makemikari asara.

3. Automated Cleaning Systems

Nekuwedzera kuri kuramba kuchiwedzera kwekugadzirwa kwesemiconductor, otomatiki yekuchenesa masisitimu yave sarudzo inosarudzika yekuchenesa yakakura-yafer. Aya masisitimu anowanzo sanganisira otomatiki ekufambisa masisitimu, akawanda-matangi ekuchenesa masisitimu, uye nemagadzirirwo ekudzora masisitimu kuti ive nechokwadi chekuchenesa mhedzisiro yewafer yega yega.

5. Future Trends

Sezvo semiconductor michina ichiramba ichidzikira, tekinoroji yekuchenesa tekinoroji iri kushanduka ichienda kune zvinobudirira uye zvine hushamwari mhinduro. Tekinoroji dzekuchenesa ramangwana dzichatarisa pane:

Sub-nanometer Particle Kubvisa: Tekinoroji iripo yekuchenesa tekinoroji inogona kubata nanometer-chikero zvimedu, asi nekumwe kudzikiswa kwehukuru hwechishandiso, kubvisa sub-nanometer zvidimbu zvinova dambudziko idzva.

Kucheneswa kweGreen uye Eco-hushamwari: Kuderedza kushandiswa kwemakemikari anokuvadza zvakatipoteredza uye kugadzira mamwe eco-hushamwari nzira dzekuchenesa, dzakadai sekuchenesa ozone uye megasonic kuchenesa, zvichawedzera kukosha.

Yepamusoro Manhanho eOtomatiki uye Hungwaru: Hungwaru masisitimu anogonesa chaiyo-nguva yekutarisa uye kugadziridzwa kweakasiyana ma paramita panguva yekuchenesa maitiro, achiwedzera kunatsiridza kuchenesa mashandiro uye kugona kugadzira.

Wafer yekuchenesa tekinoroji, senhanho yakakosha mukugadzira semiconductor, inoita basa rakakosha mukuona yakachena wafer nzvimbo kune dzinotevera maitiro. Iko kusanganiswa kwenzira dzakasiyana-siyana dzekuchenesa zvinobudirira kubvisa zvinosvibisa, zvichipa yakachena substrate pamusoro pematanho anotevera. Sezvo tekinoroji ichifambira mberi, maitiro ekuchenesa acharamba achigadziridzwa kuti asangane nezvinodiwa zvehunyoro hwepamusoro uye hurema hwakaderera mukugadzira semiconductor.

Nguva yekutumira: Oct-08-2024