Parizvino, kambani yedu inogona kuramba ichipa diki batch ye8inchN mhando yeSiC wafers, kana uine sampuli zvaunoda, ndapota inzwa wakasununguka kundibata. Tine mamwe mawafer emuenzaniso akagadzirira kutumirwa.

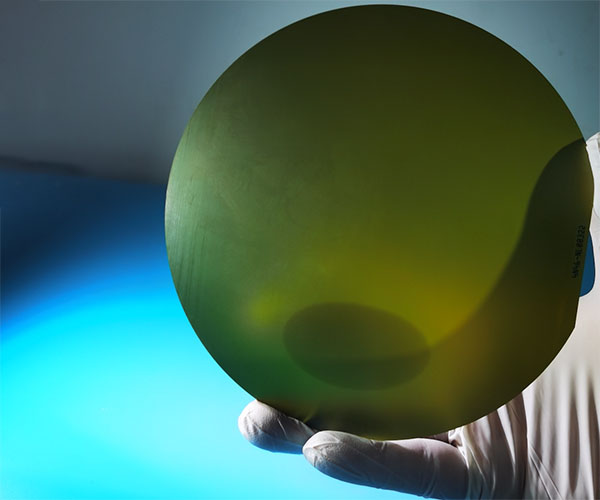

Mumunda wezvigadzirwa zve semiconductor, kambani yakaita budiriro huru mukutsvagisa nekusimudzira hukuru hukuru hweSiC makristasi. Nekushandisa kwayo makristasi embeu mushure mekutenderera kwakawanda kwekuwedzera kwedhayamita, kambani yakabudirira kukura 8-inch N-mhando SiC makristasi, ayo anogadzirisa matambudziko akaoma senge asina kuenzana tembiricha munda, kristaro kupaza uye gasi chikamu chakasvibirira kugovera mukukura kwe8-inch SIC makristasi, uye inomhanyisa kukura kwehukuru hukuru hweSic makristasi uye inogoneka kugadzirisa tekinoroji. Kusimudzira zvakanyanya kukwikwidza kwekambani muSiC single crystal substrate indasitiri. Panguva imwecheteyo, kambani inoshingairira kusimudzira kuunganidza tekinoroji uye maitiro ehukuru saizi silicon carbide substrate gadziriro yekuyedza mutsara, inosimbisa hunyanzvi hwekutsinhana uye kushandirapamwe kwemaindasitiri muminda yekumusoro uye yakadzika, uye inobatirana nevatengi kugara vachidzokorora kuita kwechigadzirwa, uye pamwe chete inosimudzira kumhanya kwemaindasitiri kushandiswa kwesilicon carbide zvinhu.

| 8inch N-mhando SiC DSP Zvinyorwa | |||||

| Number | Item | Unit | Kugadzirwa | Tsvakurudzo | Dummy |

| 1. Parameters | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | pamusoro pekutarisa | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Magetsi parameter | |||||

| 2.1 | dopant | -- | n-mhando Nitrogen | n-mhando Nitrogen | n-mhando Nitrogen |

| 2.2 | resistivity | uyo ·cm | 0.015~0.025 | 0.01~0.03 | NA |

| 3. Mechanical parameter | |||||

| 3.1 | dhayamita | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | ukobvu | μm | 500±25 | 500±25 | 500±25 |

| 3.3 | Notch orientation | ° | [1- 100]±5 | [1- 100]±5 | [1- 100]±5 |

| 3.4 | Notch Depth | mm | 1~1.5 | 1~1.5 | 1~1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Bow | μm | -25~25 | -45~45 | -65~65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Chimiro | |||||

| 4.1 | micropipe density | e/cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | metal content | maatomu/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | e/cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | e/cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | e/cm2 | ≤7000 | ≤10000 | NA |

| 5. Hunhu hwakanaka | |||||

| 5.1 | pamberi | -- | Si | Si | Si |

| 5.2 | pamusoro pekupedzisira | -- | Si-face CMP | Si-face CMP | Si-face CMP |

| 5.3 | particle | ea/wafer | ≤100(saizi≥0.3μm) | NA | NA |

| 5.4 | scratch | ea/wafer | ≤5, Hurefu Hwose≤200mm | NA | NA |

| 5.5 | Edge chips/indents/cracks/stains/contamination | -- | Hapana | Hapana | NA |

| 5.6 | Polytype nzvimbo | -- | Hapana | Nzvimbo ≤10% | Nzvimbo ≤30% |

| 5.7 | pamberi pemaka | -- | Hapana | Hapana | Hapana |

| 6. Back quality | |||||

| 6.1 | back finish | -- | C-chiso MP | C-chiso MP | C-chiso MP |

| 6.2 | scratch | mm | NA | NA | NA |

| 6.3 | Back defects kumucheto machipisi/indents | -- | Hapana | Hapana | NA |

| 6.4 | Back roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kumaka kumashure | -- | Notch | Notch | Notch |

| 7. Mupendero | |||||

| 7.1 | kumucheto | -- | Chamfer | Chamfer | Chamfer |

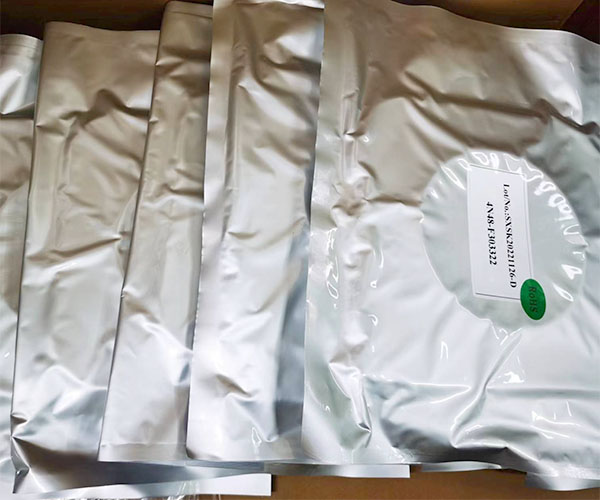

| 8. Package | |||||

| 8.1 | kurongedza | -- | Epi-yakagadzirira ne vacuum kurongedza | Epi-yakagadzirira ne vacuum kurongedza | Epi-yakagadzirira ne vacuum kurongedza |

| 8.2 | kurongedza | -- | Multi-wafer kurongedza makaseti | Multi-wafer kurongedza makaseti | Multi-wafer kurongedza makaseti |

Nguva yekutumira: Kubvumbi-18-2023