Nhanganyaya kune silicon carbide

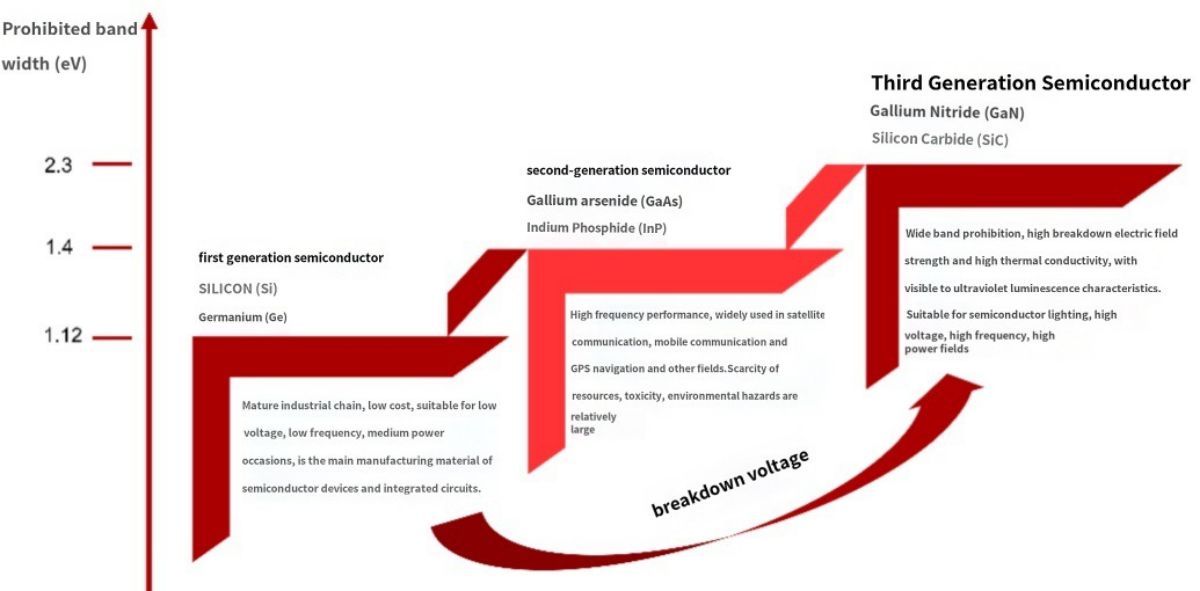

Silicon carbide (SiC) isanganiswa semiconductor zvinhu inoumbwa nekabhoni nesilicon, inova imwe yezvakakodzera zvekugadzira tembiricha yepamusoro, yakakwirira frequency, yakakwirira simba uye yakakwirira voltage zvishandiso. Kuenzaniswa neyechinyakare silicon zvinhu (Si), iro bhendi gap resilicon carbide rakapetwa katatu iro resilicon. The thermal conductivity ndeye 4-5 nguva yesilicon; Kuparara kwemagetsi ndeye 8-10 nguva yesilicon; Iyo yemagetsi saturation drift rate ndeye 2-3 nguva yesilicon, iyo inosangana nezvinodiwa zvemazuva ano indasitiri yesimba rakakura, high voltage uye yakakwirira frequency. Inonyanya kushandiswa pakugadzirwa kwepamusoro-soro, high-frequency, high-simba uye chiedza-emitting electronic components. Minda yekunyorera yakadzika inosanganisira smart grid, mota nyowani dzemagetsi, photovoltaic mhepo simba, 5G kutaurirana, etc. Silicon carbide diodes uye MOSFETs dzakashandiswa kutengeserana.

High tembiricha kuramba. Iyo bhendi gap hupamhi hwesilicon carbide ndeye 2-3 nguva yesilicon, maerekitironi haasi nyore kuchinjika patembiricha yakakwira, uye anogona kumira tembiricha yepamusoro yekushandisa, uye thermal conductivity yesilicon carbide ndeye 4-5 nguva yesilicon, zvichiita kuti mudziyo kupisa kupisa kuve nyore uye muganhu wekushanda tembiricha yakakwirira. Iyo yakanyanya tembiricha kuramba inogona kuwedzera zvakanyanya simba density uku ichidzikisa zvinodiwa pane inotonhorera system, ichiita kuti terminal ireruke uye idiki.

Kumirisana ne high pressure. Kusimba kwesimba remagetsi esilicon carbide kakapetwa ka10 kune yesilicon, iyo inokwanisa kumirisana nemagetsi epamusoro uye inokodzera zvakanyanya kumagetsi emagetsi.

High frequency resistance. Silicon carbide ine saturated electron Drift rate yakapetwa kaviri iyo yesilicon, zvichikonzera kusavapo kwekuswededza kwazvino panguva yekuvharwa, iyo inogona kunyatso vandudza switching frequency yechishandiso uye kuona miniaturization yechishandiso.

Kupera simba kwakaderera. Kuenzaniswa nesilicon zvinhu, silicon carbide ine yakaderera-kupokana uye yakaderera-kurasikirwa. Panguva imwecheteyo, iyo yakakwira bhendi-gap yakafara yesilicon carbide inoderedza zvakanyanya kudonha kwazvino uye kurasikirwa kwesimba. Mukuwedzera, iyo silicon carbide mudziyo haina ikozvino inoteedzera chiitiko panguva yekuvhara, uye kurasikirwa kwekuchinja kwakaderera.

Silicon carbide indasitiri chain

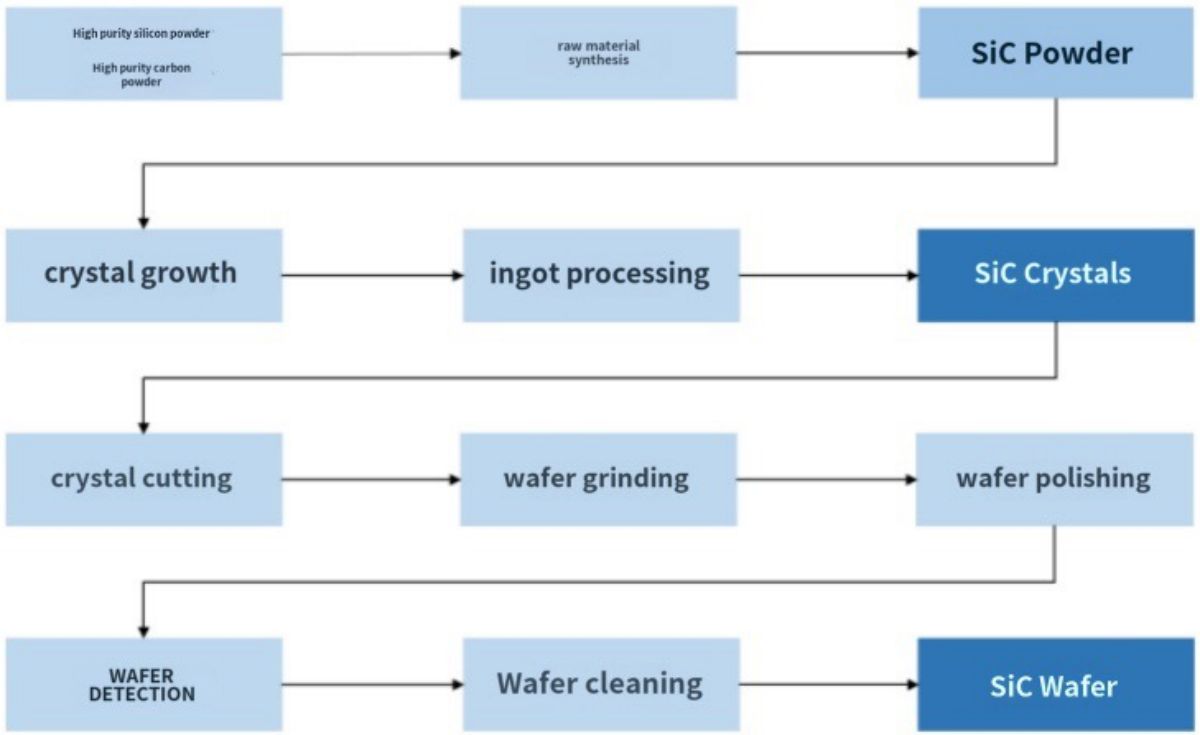

Iyo inonyanya kusanganisira substrate, epitaxy, dhizaini yedhizaini, kugadzira, kuisa chisimbiso uye zvichingodaro. Silicon carbide kubva kuzvinhu kuenda kune semiconductor simba mudziyo inowana imwechete crystal kukura, ingot slicing, epitaxial kukura, wafer dhizaini, kugadzira, kurongedza uye mamwe maitiro. Mushure mekugadzirwa kwesilicon carbide poda, iyo silicon carbide ingot inogadzirwa kutanga, uye ipapo iyo silicon carbide substrate inowanikwa nekucheka, kukuya nekupukuta, uye iyo epitaxial sheet inowanikwa ne epitaxial kukura. Iyo epitaxial wafer inogadzirwa nesilicon carbide kuburikidza ne lithography, etching, ion implantation, simbi passivation uye mamwe maitiro, iyo wafer inochekwa kuita kufa, mudziyo unoputirwa, uye mudziyo unosanganiswa kuita yakakosha shell uye inounganidzwa mune module.

Kumusoro kweiyo indasitiri ketani 1: substrate - crystal kukura ndiyo yakakosha process link

Silicon carbide substrate accounts inosvika makumi mana nenomwe muzana yemutengo wesilicon carbide zvishandiso, iyo yepamusoro yekugadzira zvipingamupinyi zvehunyanzvi, kukosha kukuru, ndiyo musimboti weramangwana rakakura-maindasitiri eSiC.

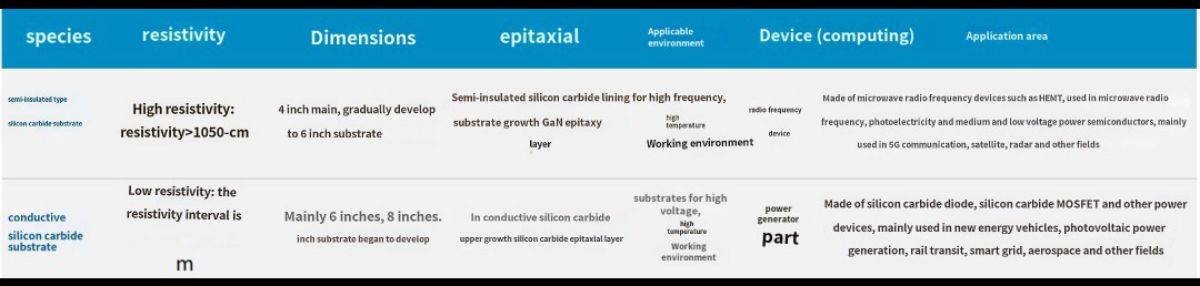

Kubva pakuona kwe electrochemical property musiyano, silicon carbide substrate zvinhu zvinogona kukamurwa kuita conductive substrates (resistivity region 15~30mΩ·cm) uye semi-insulated substrates (resistivity yakakwirira kupfuura 105Ω·cm). Aya marudzi maviri emasubstrates anoshandiswa kugadzira disitere zvishandiso semagetsi emagetsi neredhiyo frequency zvishandiso zvakateerana mushure mekukura epitaxial. Pakati pavo, semi-insulated silicon carbide substrate inonyanya kushandiswa mukugadzira gallium nitride RF zvishandiso, photoelectric zvishandiso uye zvichingodaro. Nekukura gan epitaxial layer pane semi-insulated SIC substrate, iyo sic epitaxial ndiro inogadzirwa, inogona kugadziridzwa zvakare muHEMT gan iso-nitride RF zvishandiso. Conductive silicon carbide substrate inonyanya kushandiswa mukugadzira magetsi emagetsi. Yakasiyana neyakajairwa silicon simba rekugadzira mudziyo, iyo silicon carbide simba mudziyo haigone kugadzirwa zvakananga pasilicon carbide substrate, iyo silicon carbide epitaxial layer inoda kukura pane conductive substrate kuti iwane silicon carbide epitaxial sheet, uye epitaxial layer inogadzirwa paSchottky diode, MOS uye mamwe maturusi emagetsi.

Silicon carbide poda yakagadziridzwa kubva pakuchena kwekabhoni poda uye yakakwira kuchena silicon poda, uye saizi dzakasiyana dzesilicon carbide ingot dzakarimwa pasi penzvimbo yakakosha yekupisa, uyezve silicon carbide substrate yakagadzirwa kuburikidza nemaitiro akawanda ekugadzirisa. Iyo core process inosanganisira:

Raw material synthesis: Iyo yakakwirira-kuchena silicon poda + toner inosanganiswa zvinoenderana nefomati, uye maitiro anoitwa mukamuri yekupindura pasi peiyo tembiricha yepamusoro pamusoro pe2000 ° C kuti igadzirise iyo silicon carbide zvidimbu zvine chaiyo crystal mhando uye particle size. Zvino kuburikidza nekupwanya, kuongorora, kuchenesa uye mamwe maitiro, kusangana nezvinodiwa zvekuchena kwesilicon carbide poda zviwanikwa.

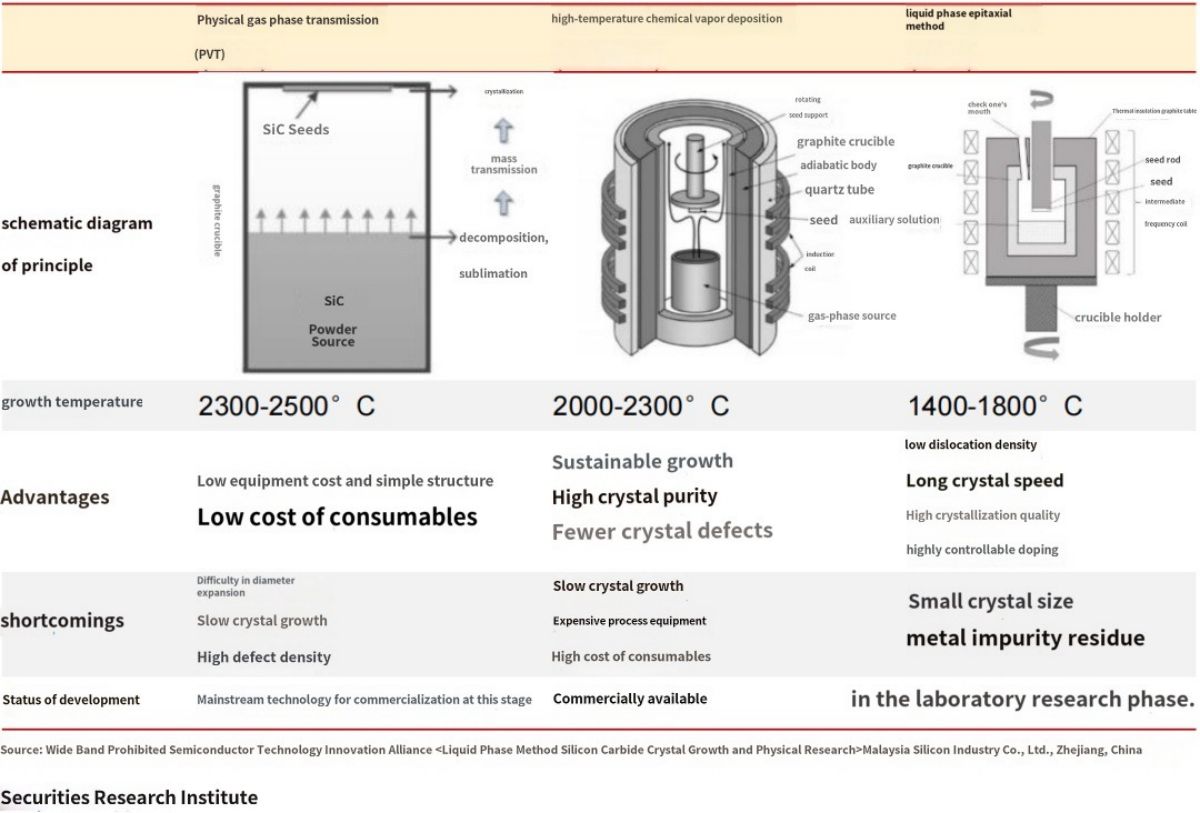

Kukura kweCrystal ndiyo musimboti wekuita kwesilicon carbide substrate kugadzira, iyo inosarudza magetsi emagetsi esilicon carbide substrate. Parizvino, nzira huru dzekukura kwekristaro ndeyemuviri mhute kutamiswa (PVT), yakanyanya tembiricha kemikari vapor deposition (HT-CVD) uye liquid phase epitaxy (LPE). Pakati pavo, nzira yePVT ndiyo nzira huru yekukura kwekutengesa kweSiC substrate parizvino, ine hunyanzvi hwekukura uye inonyanya kushandiswa muinjiniya.

Kugadzirira kweSiC substrate kwakaoma, kunotungamirira kumutengo wayo wepamusoro

Tembiricha yekudzora munda yakaoma: Si crystal rod kukura kunongoda 1500 ℃, nepo SiC crystal rod inoda kukura pakupisa kwakanyanya pamusoro pe2000 ℃, uye kune anopfuura 250 SiC isomers, asi iyo huru 4H-SiC single crystal chimiro chekugadzirwa kwemidziyo yemagetsi, kana isiri iyo chaiyo yekutonga, ichawana mamwe makristasi maitiro. Pamusoro pezvo, tembiricha yekushisa mu crucible inotaridza mwero weSiC sublimation kutamiswa uye kurongeka uye kukura maitiro emaatomu egasi pane yekristaro interface, iyo inokanganisa chiyero chekukura kwekristaro uye mhando yekristaro, saka zvinodikanwa kuumba yakarongeka tembiricha yekudzora munda. Kuenzaniswa neSi zvinhu, mutsauko mukugadzirwa kweSiC uri zvakare mune yakakwira tembiricha maitiro senge yakakwira tembiricha ion kuisirwa, yakanyanya tembiricha oxidation, yakanyanya tembiricha activation, uye yakaoma mask process inodiwa neaya maitiro ekushisa.

Slow crystal kukura: kukura kweSi crystal rod inogona kusvika 30 ~ 150mm / h, uye kugadzirwa kwe1-3m silicon crystal rod inongotora zuva rimwe chete; SiC crystal rod ine nzira yePVT semuenzaniso, chiyero chekukura chinenge 0.2-0.4mm / h, mazuva manomwe kukura zvishoma kudarika 3-6cm, chiyero chekukura chiri pasi pe1% yezvinhu zvesilicon, simba rekugadzira rakanyanya kuderera.

High chigadzirwa parameters uye yakaderera goho: core parameters of SiC substrate zvinosanganisira microtubule density, dislocation density, resistivity, warpage, pamusoro roughness, etc. Iyo yakaoma hurongwa engineering kuronga maatomu mu yakavharwa yakakwirira-tembiricha chamber uye akazara crystal kukura, apo kudzora parameter indexes.

Nyaya yacho ine kuoma kwakanyanya, brittleness yakakwirira, nguva yakareba yekucheka uye kupfeka kwepamusoro: SiC Mohs kuoma kwe9.25 ndeyechipiri kune diamond chete, izvo zvinotungamirira kukuwedzera kukuru kwekuoma kwekucheka, kugaya uye kupukuta, uye zvinotora anenge maawa 120 kutema 35-40 zvidimbu zve 3cm gobvu ingot. Uye zvakare, nekuda kweiyo yakanyanya brittleness yeSiC, wafer kugadzirisa kupfeka kuchave kwakawanda, uye reshiyo yekubuda ingangoita 60%.

Mafambiro ebudiriro: Kuwedzera saizi + kuderera kwemutengo

Musika wepasi rose weSiC 6-inch vhoriyamu yekugadzira mutsara uri kukura, uye makambani anotungamira apinda mumusika we8-inch. Mapurojekiti ekusimudzira mudzimba anonyanya kuita 6 inches. Parizvino, kunyangwe makambani mazhinji epamba achiri akavakirwa pamitsara yekugadzira 4-inch, asi indasitiri iri kukura zvishoma nezvishoma kusvika pa6-inch, nekukura kwe6-inch inotsigira tekinoroji yemidziyo, yepamba SiC substrate tekinoroji iri kuwedzera zvishoma nezvishoma hupfumi hwehukuru hwemitsara yekugadzira mikuru icharatidzwa, uye yazvino 6-inch misa yekugadzira nguva gap yakadzikira kusvika pamakore manomwe. Hukuru hwewafesi hunogona kuunza kuwedzera kwehuwandu hwemachipisi ega, kuvandudza mwero wegoho, uye kuderedza chikamu chemupendero machipisi, uye mutengo wekutsvagisa nekusimudzira uye kurasikirwa kwegoho uchachengetwa unosvika 7%, nekudaro kuvandudza kushandiswa kwewafer.

Pachine matambudziko akawanda mukugadzira mudziyo

Kutengeswa kweSiC diode kunovandudzwa zvishoma nezvishoma, parizvino, vagadziri vedzimba vanoverengeka vakagadzira zvigadzirwa zveSiC SBD, zvepakati nepamusoro voltage SiC SBD zvigadzirwa zvine kugadzikana kwakanaka, mumotokari OBC, kushandiswa kweSiC SBD + SI IGBT kuwana yakagadzikana density iripo. Parizvino, hapana zvipingamupinyi mukugadzira patent yeSiC SBD zvigadzirwa muChina, uye gaka nenyika dzekunze idiki.

SiC MOS ichine matambudziko mazhinji, pachine mukaha pakati peSiC MOS nevagadziri vekunze, uye chikuva chakakodzera chekugadzira chichiri kuvakwa. Parizvino, ST, Infineon, Rohm uye mamwe 600-1700V SiC MOS akawana kugadzirwa kwakawanda uye akasainwa uye akatumirwa nemaindasitiri mazhinji ekugadzira, nepo dhizaini yazvino yeSiC MOS dhizaini yakapedzwa, huwandu hwevagadziri vekugadzira vari kushanda nemachira padanho rekuyerera kwewafer, uye gare gare kuongororwa kwevatengi kuchiri kuda imwe nguva, saka kuchine nguva yakakura yekutengeserana.

Parizvino, iyo planar dhizaini ndiyo yakasarudzika sarudzo, uye mhando yemugero inoshandiswa zvakanyanya mumunda wekudzvanya kwepamusoro mune ramangwana. Planar structure SiC MOS vagadziri vakawanda, iyo planar chimiro haisi nyore kuburitsa matambudziko emunharaunda yekuputsika kana ichienzaniswa negorofu, inokanganisa kugadzikana kwebasa, pamusika pazasi 1200V ine huwandu hwakawanda hwekushandisa kukosha, uye iyo planar chimiro chiri nyore pakupera kwekugadzira, kusangana nekugadzirwa uye mutengo wekutonga zvinhu zviviri. Iyo groove mudziyo ine zvakanakira zvakanyanyisa kuderera parasitic inductance, kukurumidza kushandura kumhanya, kurasikirwa kwakaderera uye kuita kwakanyanya.

2--SiC wafer nhau

Silicon carbide musika kugadzirwa uye kukura kwekutengesa, teerera kune kusaenzana kwechimiro pakati pekupa uye kudiwa

Nekukurumidza kukura kwemusika kudiwa kweakakwira-frequency uye yakakwirira-simba magetsi emagetsi, iyo yemuviri muganho bhodhoro resilicon-based semiconductor zvishandiso zvishoma nezvishoma zvave mukurumbira, uye yechitatu-chizvarwa semiconductor zvinhu zvinomiririrwa nesilicon carbide (SiC) zvishoma nezvishoma zvave maindasitiri. Kubva pakuona kwezvinhu, silicon carbide ine 3 times the band gap width yesilicon material, 10 times the critical breakdown electric field simba, 3 times the thermal conductivity, saka silicon carbide magetsi maturusi akakodzera kumhepo yakawanda, high pressure, kupisa kwepamusoro uye mamwe maapplication, anobatsira kuvandudza kushanda uye simba remagetsi emagetsi emagetsi masisitimu.

Parizvino, maSiC diodes uye SiC MOSFETs zvishoma nezvishoma akatamira kumusika, uye kune zvimwe zvigadzirwa zvakakura, pakati peiyo maSiC diode anoshandiswa zvakanyanya panzvimbo yesilicon-based diode mune mamwe minda nekuti ivo havana mukana wekudzosera kudzoreredza kubhadharisa; SiC MOSFET inoshandiswawo zvishoma nezvishoma mumotokari, kuchengetedza simba, murwi wekuchaja, photovoltaic nemamwe minda; Mundima yekushandiswa kwemotokari, maitiro emodularization ari kuramba achiwedzera mukurumbira, kuita kwepamusoro kweSiC kunoda kuvimba nematanho epamberi ekurongedza kuti zvibudirire, nehunyanzvi neyakakura kuvharika kwegoko seyakanyanya, remangwana kana kukusimudzira kwekuisa chisimbiso kwepurasitiki, hunhu hwayo hwekusimudzira hwakanyanya kukodzera maSiC modules.

Silicon carbide mutengo unodzikira kumhanya kana kupfuura fungidziro

Iko kushandiswa kwesilicon carbide zvishandiso kunonyanya kuderedzwa nemutengo wepamusoro, mutengo weSiC MOSFET pasi pezinga rimwechete wakakwira 4 nguva kupfuura iyo yeSi-based IGBT, izvi zvinodaro nekuti maitiro esilicon carbide akaomarara, umo kukura kwekristaro imwe chete uye epitaxial hakusi kungoomesesa pane zvakatipoteredza, asiwo kukura kwekukura kunononoka, uye kucheka kwekristaro kugadziridza kunofanira kupinda muchikamu chekucheka. Zvichienderana nehunhu hwayo hwezvinhu uye immature process tekinoroji, goho remumba substrate iri pasi pe50%, uye zvinhu zvakasiyana zvinotungamira kune yakakwira substrate uye epitaxial mitengo.

Nekudaro, mutengo wekuumbwa kwesilicon carbide zvishandiso nesilicon-based zvishandiso zvakapesana, iyo substrate uye epitaxial mitengo yepamberi chiteshi account ye47% uye 23% yemudziyo wese zvakateerana, inokwana 70%, dhizaini yedhizaini, kugadzira uye kuvhara malink eakaundi yekumashure chiteshi chete 30%, mutengo wekugadzirwa kweiyo silicon-yakavakirwa dhizaini yakagadziriswa kumashure kweiyo silicon-yakavakirwa dhizaini. 50%, uye substrate mutengo maakaunzi chete 7%. Chiitiko chekukosha kwesilicon carbide industry chain upside down inoreva kuti upstream substrate epitaxy vagadziri vane kodzero huru yekutaura, inova kiyi yekurongeka kwemabhizinesi epamba neekunze.

Kubva pakusimba kwekuona pamusika, kuderedza mutengo wesilicon carbide, kuwedzera pakuvandudza silicon carbide refu crystal uye slicing process, kuwedzera saizi yewaferi, inovawo nzira yakakura yekusimudzira semiconductor munguva yakapfuura, Wolfspeed data inoratidza kuti silicon carbide substrate kukwidziridzwa kubva pa6 inches kusvika 80% kugadzirwa, inogona kuwedzera 80% kugadzirwa. vandudza goho. Inogona kuderedza mari yakabatanidzwa yeyuniti ne50%.

2023 inozivikanwa se "8-inch SiC gore rekutanga", gore rino, vagadziri vemukati uye vekunze silicon carbide vari kukurumidza kurongeka kwe8-inch silicon carbide, seWolfspeed inopenga yekudyara yemadhora 14.55 bhiriyoni emadhora eku silicon carbide yekuwedzera kugadzirwa, chikamu chakakosha icho chiri kuvakwa kwe8-inch simbi yekugadzira SiC. kumakambani mazhinji; Domestic Tianyue Advanced naTianke Heda vakasainawo zvibvumirano zvenguva refu neInfineon kuti vape 8-inch silicon carbide substrates mune ramangwana.

Kutanga kubva gore rino, silicon carbide ichawedzera kubva pa6 inches kusvika pa8 inches, Wolfspeed inotarisira kuti panosvika 2024, iyo unit chip mutengo we8 inches substrate ichienzaniswa neiyo unit chip mutengo we6 inches substrate muna 2022 ichaderedzwa neinopfuura makumi matanhatu muzana, uye kuderera kwemitengo kuchaenderera mberi nekuvhura musika wekushandisa. Ikozvino musika wekugovaniswa wezvigadzirwa zve8-inch uri pasi pe2%, uye chikamu chemusika chinotarisirwa kukura kusvika pagumi neshanu muzana panosvika 2026.

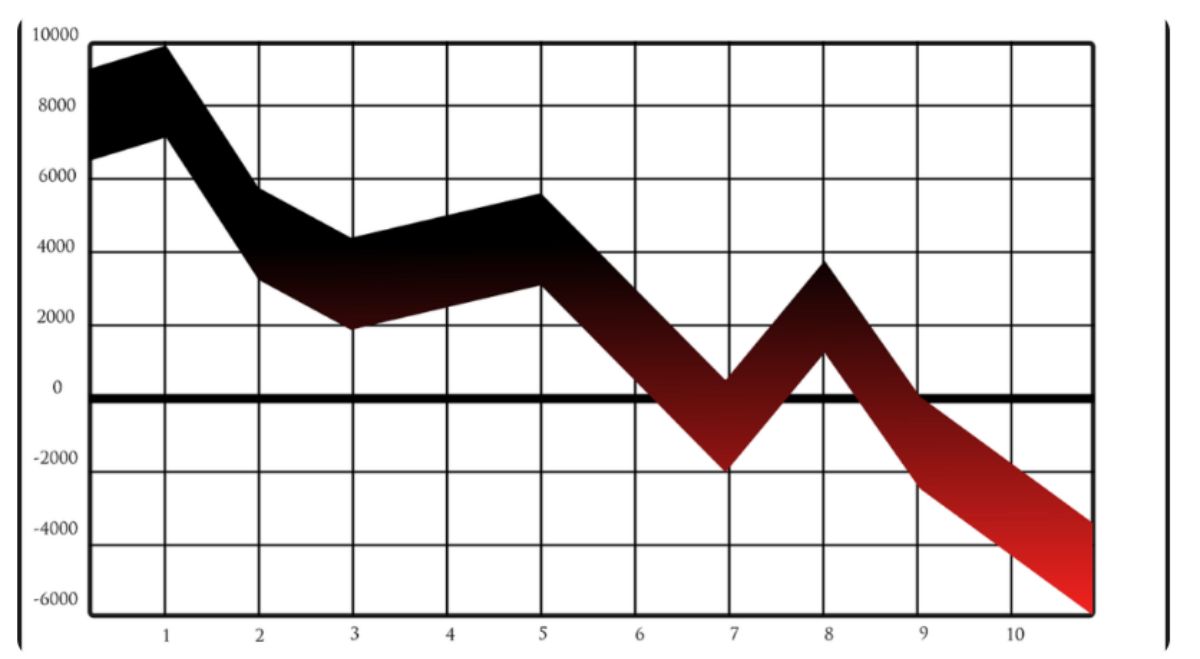

Muchokwadi, chiyero chekuderera mumutengo wesilicon carbide substrate inogona kudarika fungidziro yevanhu vazhinji, iyo iripo yemusika inopa ye6-inch substrate ndeye 4000-5000 yuan / chidimbu, zvichienzaniswa nekutanga kwegore yadonha zvakanyanya, inotarisirwa kuwira pasi pe4000 yuan gore rinouya, zvakakosha kucherechedza kuti kune vamwe vanogadzira mutengo wakaderera pamusika, mutengo wakaderera. iyo modhi yehondo yemitengo, yakanyanya kuisirwa musilicon carbide substrate supply yave yakaringana mumunda wakaderera-voltage, vagadziri vepamba nevekunze vari kuwedzera zvine hukasha kugona kwekugadzira, kana kurega iyo silicon carbide substrate yakawandisa kupfuura yaifungidzirwa.

Nguva yekutumira: Jan-19-2024