1. Nhanganyaya

Kunyangwe makumi emakore ekutsvagisa, heteroepitaxial 3C-SiC yakakura pasilicon substrates haisati yawana yakakwana mhando yekristaro yezvigadzirwa zvemagetsi zveindasitiri. Kukura kunowanzoitwa paSi (100) kana Si (111) substrates, imwe neimwe ichiratidza matambudziko akasiyana: anti-phase domains ye (100) uye kupaza kwe (111). Kunyange zvazvo [111] -mafirimu anotarisa anoratidza unhu hunovimbisa hwakadai sekuderedzwa kwehurema, kuvandudzwa kwepamusoro morphology, uye kuderera kwekunetseka, mamwe maitiro akaita se (110) uye (211) anoramba asina kudzidza. Mashoko aripo anoratidza kuti mamiriro ekukura akakwana anogona kunge ari kutarisisa, achinetsa kuferefeta kwakarongeka. Zvinonyanya kukosha, kushandiswa kwepamusoro-Miller-index Si substrates (eg, (311), (510)) ye 3C-SiC heteroepitaxy haina kumbotaurwa, ichisiya nzvimbo inokosha yekuongorora tsvakurudzo pamusoro pemaitiro-anotsamira maitiro ekukura.

2. Kuedza

Iwo 3C-SiC maseru akaiswa kuburikidza nemhepo-pressure kemikari vapor deposition (CVD) uchishandisa SiH4/C3H8/H2 precursor magasi. Iwo ma substrates aive 1 cm² Si wafers ane maitiro akasiyana: (100), (111), (110), (211), (311), (331), (510), (553), uye (995). Ese ma substrates aive pa-axis kunze kwe (100), uko 2 ° off-cut wafers akaedzwa zvakare. Kucheneswa kwekutanga-kukura kwaisanganisira ultrasonic degreasing mumethanol. Protocol yekukura yaisanganisira native oxide kubviswa kuburikidza neH2 annealing pa1000 ° C, inoteverwa neyakajairwa nhanho mbiri: carburization kwemaminitsi gumi pa1165 ° C ne12 sccm C3H8, ipapo epitaxy kwemaminetsi makumi matanhatu pa1350 ° C (C / Si ratio = 4) uchishandisa 1.5 sccm 8 CH4 uye 1.5 sccm H4. Kukura kwega kwega kwaisanganisira mana kusvika mashanu akasiyana maSi orientation, aine imwechete (100) referensi wafer.

3. Migumisiro uye Hurukuro

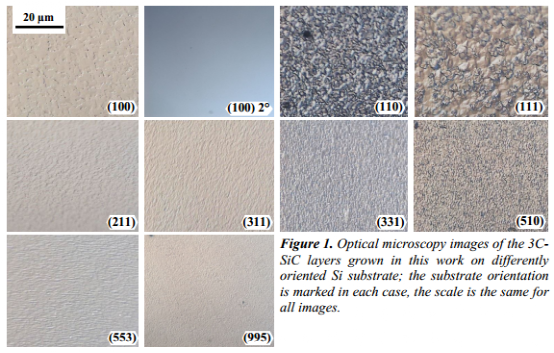

Iyo morphology ye3C-SiC mitsetse yakakura pane dzakasiyana-siyana dzeSi substrates (Fig. 1) yakaratidza maitiro akasiyana epamusoro uye roughness. Zvinotaridzika, masampuli akakura paSi (100), (211), (311), (553), uye (995) akaonekwa segirazi, asi mamwe aibva kumukaka (331), (510)) kusvika kugomarara (110), (111)). Nzvimbo dzakatsetseka (inoratidza yakanakisa microstructure) yakawanikwa pa (100) 2 ° kure uye (995) substrates. Zvinoshamisa kuti, ese akaturikidzana akaramba akatsemuka-asina kutonhora mushure mekutonhodza, kusanganisira iyo inowanzo kunetseka-inowanzoitika 3C-SiC (111). Iyo shoma saizi yemuenzaniso inogona kunge yakadzivirira kutsemuka, kunyangwe mamwe masampuli airatidza kukotama (30-60 μm kutsauka kubva pakati kuenda kumucheto) inowonekwa pasi peoptical microscopy pa1000 × magnification nekuda kwekuwanda kwekushushikana kwekupisa. Matunhu akakotamiswa akakura paSi(111), (211), uye (553) ma substrates airatidza maumbirwo airatidza kuomarara, zvinoda rimwe basa rekuedza uye redzidziso kuti rienderane necrystallographic orientation.

Mufananidzo 1 unopfupikisa XRD uye AFM (kuvheneka pa 20 × 20 μ m2) mhedzisiro ye3C-SC mitsetse inokura paSi substrates ine maitiro akasiyana.

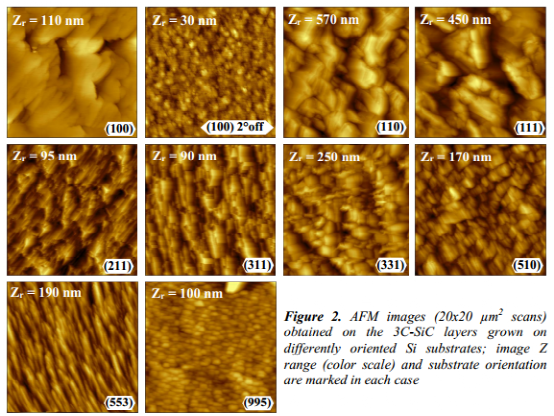

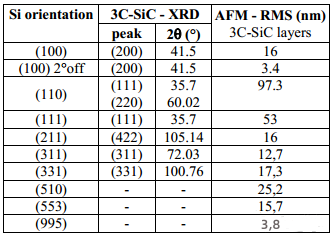

Atomic force microscopy (AFM) mifananidzo (Fig. 2) yakatsigira maonero ekuona. Root-mean-square (RMS) tsika dzakasimbisa nzvimbo dzakatsetseka pa (100)2° off uye (995) substrates, dzine zviyo zvakaita sezviyo zvine 400-800 nm lateral dimensions. Iyo (110)-yakakura layer ndiyo yaive yakaomarara, ukuwo yakarebesa uye/kana mativi anoenderana neapo neapo miganhu yakapinza yaionekwa mune mamwe maitiro ((331), (510)). X-ray diffraction (XRD) θ-2θ scans (yakapfupikiswa muTebhurari 1) yakaratidza kubudirira heteroepitaxy kune yakaderera-Miller-index substrates, kunze kweSi(110) iyo yairatidza yakasanganiswa 3C-SiC(111) uye (110) mapeaks anoratidza polycrystallinity. Uku kusanganiswa kwekutarisa kwakambotaurwa nezveSi (110), kunyangwe zvimwe zvidzidzo zvakaona zvakasarudzika (111) -yakatarisana 3C-SiC, zvichiratidza kukura kwemamiriro ekugadzirisa kwakakosha. KuMiller indices ≥5 ((510), (553), (995)), hapana nhongonya dzeXRD dzakaonekwa muyakajairwa θ-2θ kumisikidzwa sezvo idzi ndege dzepamusoro-soro dzisiri kusiyanisa mune iyi geometry. Kusavapo kweiyo yakaderera-index 3C-SiC peaks (eg, (111), (200)) inoratidzira imwe-crystalline kukura, ichida sampuli tilting kuona diffraction kubva pasi-index ndege.

Mufananidzo 2 unoratidza kuverenga kwekona yendege mukati meCFC crystal chimiro.

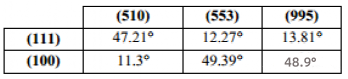

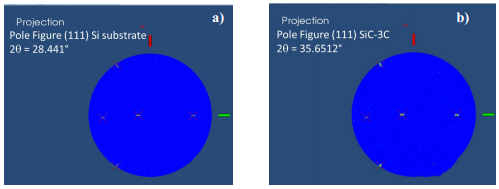

Iyo yakaverengerwa crystallographic angles pakati pepamusoro-index uye yakaderera-index ndege (Table 2) yakaratidza misorientations yakakura (> 10 °), ichitsanangura kusavapo kwavo muyero θ-2θ scans. Pole figure analysis saka yakaitwa pa(995)-yakatarisana nesample nekuda kweiyo isina kujairika granular morphology (inogona kubva pakukura kana twinning) uye kushomeka kwakaderera. Iyo (111) nhamba yemapuranga (Fig. 3) kubva kuSi substrate uye 3C-SiC layer yakada kufanana, ichisimbisa epitaxial kukura pasina twinning. Nzvimbo yepakati yakaonekwa pa χ≈15 °, inoenderana neiyo theoretical (111) - (995) angle. Mavara matatu akaenzana-akaenzana akaonekwa panzvimbo yaitarisirwa (χ=56.2°/φ=269.4°, χ=79°/φ=146.7° uye 33.6°), kunyange zvazvo nzvimbo isina kusimba isingatarisirwi pa χ=62°/φ=93.3° inoda kumwe kuongorora. Hunhu hwekristaro, hunoongororwa kuburikidza nehupamhi hwemavara mu φ-scans, hunoratidzika kunge huchivimbisa, kunyangwe kuyerwa kwe curve kuyerwa kunodiwa pahuwandu. Pole nhamba dze (510) uye (553) samples dzinosara kuti dzipedziswe kuratidza zvavanofungidzira epitaxial nature.

Mufananidzo 3 unoratidza XRD peak diagram yakanyorwa pa (995) yakatarisana nemuenzaniso, iyo inoratidza (111) ndege dzeSi substrate (a) uye 3C-SiC layer (b).

4. Mhedziso

Heteroepitaxial 3C-SiC kukura kwakabudirira pane dzakawanda Si orientations kunze kwe (110), iyo yakaburitsa polycrystalline zvinhu. Si (100) 2 ° kure uye (995) substrates yakagadzira akatsetseka akaturikidzana (RMS <1 nm), nepo (111), (211), uye (553) airatidza kukotama kwakakosha (30-60 μm). High-index substrates inoda advanced XRD characterization (semuenzaniso, nhamba dzemapole) kusimbisa epitaxy nekuda kwekushaikwa θ-2θ peaks. Basa rinoenderera mberi rinosanganisira kuzunungusa curve kuyerwa, Raman stress ongororo, uye kuwedzera kune yakawedzera-indekisi yekumisikidza kupedzisa ichi chidzidzo chekuongorora.

Semugadziri akanyatsobatanidzwa, XKH inopa nyanzvi dzakagadziridzwa masevhisi ekugadzirisa ane yakazara portfolio yesilicon carbide substrates, inopa akajairwa uye akasiyana marudzi anosanganisira 4H/6H-N, 4H-Semi, 4H/6H-P, uye 3C-SiC, inowanikwa mumadhayamita kubva pa2-inch kusvika 12-inch. Yedu yekupedzisira-kusvika-kumagumo hunyanzvi mukukura kwekristaro, kunyatsogadzira, uye vimbiso yemhando inovimbisa mhinduro dzakagadzirirwa dzemagetsi emagetsi, RF, uye maapplication ari kubuda.

Nguva yekutumira: Aug-08-2025