Kubva kuma1980, kuwanda kwekubatanidza kwemaseketi emagetsi kwave kuwedzera pamwero wepagore we1.5 × kana nekukurumidza. Kubatanidzwa kwepamusoro kunotungamira kune yakakura densities ikozvino uye kupisa chizvarwa panguva yekushanda.Kana isina kubviswa zvakanaka, kupisa uku kunogona kukonzera kutadza kwekupisa uye kuderedza hupenyu hwezvikamu zvemagetsi.

Kuti isangane nekuwedzera kwekudziya kwekutonga zvinodiwa, advanced electronic packaging materials ane superior thermal conductivity zviri kuongororwa zvakanyanya uye kugadziridzwa.

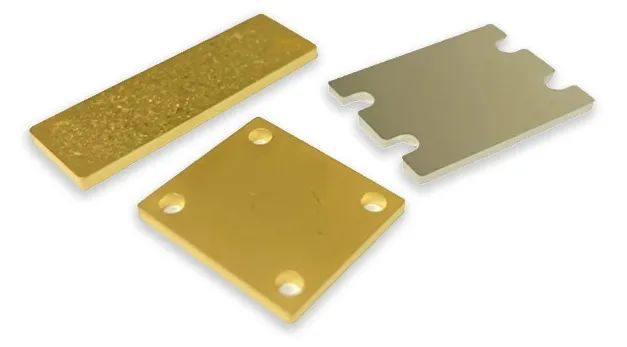

Dhaimondi/mhangura inoumbwa zvinhu

01 Dhaimondi neMhangura

Zvechinyakare zvekurongedza zvinhu zvinosanganisira ceramics, mapurasitiki, simbi, uye alloys avo. Ceramics seBeO neAlN inoratidza CTEs inoenderana semiconductors, yakanaka kugadzikana kwemakemikari, uye ine mwero kupisa conductivity. Nekudaro, yavo yakaoma kugadzirisa, kudhura kwakanyanya (kunyanya muchetura BeO), uye brittleness inoganhura maapplication. Kurongedza kwepurasitiki kunopa mutengo wakaderera, huremu huremu, uye insulation asi inotambura nekushomeka kwemafuta ekupisa uye kusagadzikana kwepamusoro-tembiricha. Simbi dzakachena (Cu, Ag, Al) dzine yakanyanya kupisa conductivity asi yakawandisa CTE, nepo alloys (Cu-W, Cu-Mo) inokanganisa mashandiro emafuta. Nekudaro, zvinyowani zvekurongedza zvinhu zvinoyera yakakwira yekupisa conductivity uye yakakwana CTE inodiwa nekukurumidza.

| Kusimbisa | Thermal Conductivity (W/(m·K)) | CTE (×10⁻⁶/℃) | Density (g/cm³) |

| Diamond | 700–2000 | 0.9–1.7 | 3.52 |

| BeO zvidimbu | 300 | 4.1 | 3.01 |

| AlN zvikamu | 150–250 | 2.69 | 3.26 |

| SiC zvimedu | 80–200 | 4.0 | 3.21 |

| B₄C zvimedu | 29–67 | 4.4 | 2.52 |

| Boron fiber | 40 | ~5.0 | 2.6 |

| TiC zvikamu | 40 | 7.4 | 4.92 |

| Al₂O₃ zvimedu | 20–40 | 4.4 | 3.98 |

| SiC ndebvu | 32 | 3.4 | - |

| Si₃N₄ zvimedu | 28 | 1.44 | 3.18 |

| TiB₂ zvimedu | 25 | 4.6 | 4.5 |

| SiO₂ zvimedu | 1.4 | <1.0 | 2.65 |

Diamond, iyo yakaomesesa inozivikanwa yakasikwa zvinhu (Mohs 10), inewo yakasarudzikathermal conductivity (200–2200 W/(m·K)).

Diamond micro-upfu

Mhangura, pamwe high thermal/electric conductivity (401 W/(m·K)), ductility, uye mutengo wakanaka, unoshandiswa zvakanyanya muICs.

Kubatanidza zvinhu izvi,diamond/mhangura (Dia/Cu) zvinoumba-neCu sematrix uye dhaimondi sekusimbisa-zviri kubuda sechizvarwa chinotevera chemafuta ekutonga zvinhu.

02 Nzira Dzakakosha dzekugadzira

Nzira dzakajairika dzekugadzira madhaimani / mhangura dzinosanganisira: simbi yehupfu, kudziya kwepamusoro uye nzira yekudzvanya, nzira yekunyungudutsa, nzira yekuburitsa plasma sintering, nzira yekupfapfaidza inotonhora, nezvimwe.

Kuenzanisa kweakasiyana nzira dzekugadzirira, maitiro uye zvivakwa zve single-particle size diamond / copper composite

| Parameter | Upfu Metallurgy | Vacuum Kupisa-Kudzvanya | Spark Plasma Sintering (SPS) | High-Pressure High-Temperature (HPHT) | Cold Spray Deposition | Melt Infiltration |

| Diamond Type | MBD8 | HFD-D | MBD8 | MBD4 | PDA | MBD8/HHD |

| Matrix | 99.8% Cu hupfu | 99.9% electrolytic Cu poda | 99.9% Cu hupfu | Alloy/pure Cu poda | Pure Cu hupfu | Pure Cu yakawanda / tsvimbo |

| Interface Modification | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Chikamu Chekukura (μm) | 100 | 106–125 | 100–400 | 20–200 | 35–200 | 50–400 |

| Chikamu chevhoriyamu (%) | 20–60 | 40–60 | 35–60 | 60–90 | 20–40 | 60–65 |

| Tembiricha (°C) | 900 | 800–1050 | 880–950 | 1100–1300 | 350 | 1100–1300 |

| Pressure (MPa) | 110 | 70 | 40–50 | 8000 | 3 | 1–4 |

| Nguva (min) | 60 | 60–180 | 20 | 6–10 | - | 5–30 |

| Relative Density (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Performance | ||||||

| Optimal Thermal Conductivity (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Common Dia/Cu composite matekiniki anosanganisira:

(1)Upfu Metallurgy

Musanganiswa wedhaimani / Cu poda inoumbwa uye yakanyungudutswa. Kunyange ichidhura-inoshanda uye iri nyore, iyi nzira inoburitsa mashoma density, inhomogeneous microstructures, uye akaganhurirwa sampuli zviyero.

Sintering unit

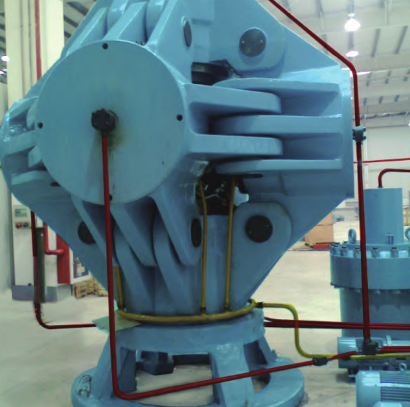

(1)High-Pressure High-Temperature (HPHT)

Ichishandisa michina yemhando dzakawanda, Cu yakanyungudutswa inopinda mumadhaimani pasi pemamiriro ezvinhu akanyanya, ichigadzira makombiji akaomarara. Nekudaro, HPHT inoda mold inodhura uye haina kukodzera kugadzirwa kwakakura.

Cubic press

(1)Melt Infiltration

Molten Cu inopinda madhaimondi preforms kuburikidza nekudzvanywa-inobatsira kana capillary-inofambiswa infiltration. Macomposites anobuditsa anowana>446 W/(m·K) thermal conductivity.

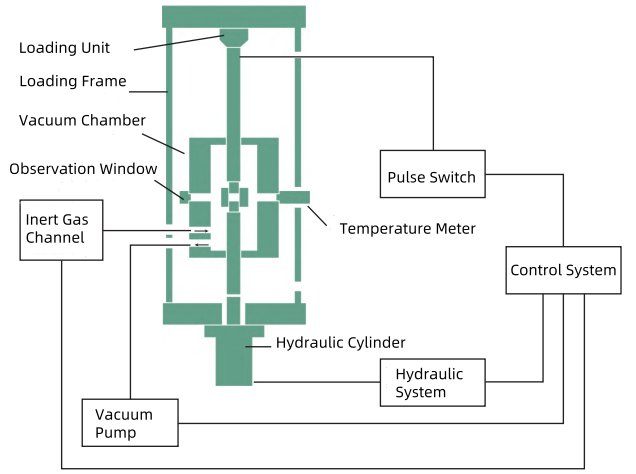

(2)Spark Plasma Sintering (SPS)

Pulsed ikozvino nekukurumidza siters yakasanganiswa poda pasi pekumanikidzwa. Kunyangwe ichishanda, kuita kweSPS kunodzikisira pazvikamu zvedhaimondi> 65 vol%.

Schematic diagram ye discharge plasma sintering system

(5) Cold Spray Deposition

Hupfu hunokwidziridzwa uye hunoiswa pane substrates. Iyi nzira yekukwira inotarisana nematambudziko mukutonga kwepamusoro uye kusimbiswa kwekuita kwekushisa.

03 Interface Kugadziriswa

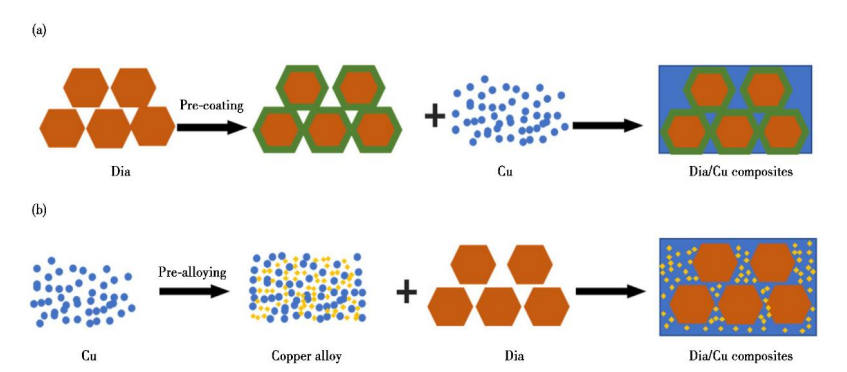

Pakugadzirirwa kwezvinhu zvinosanganiswa, kunyorova pakati pezvikamu chinhu chinodiwa cheiyo composite process uye chinhu chakakosha chinokanganisa chimiro chechimiro uye chimiro chekubatanidza bonding. Iyo isiri-wetting mamiriro pakusangana pakati pedhaimani neCu inotungamira kune yakanyanya kukwirisa interface yekupisa kupisa. Naizvozvo, zvakakosha kuita shanduko yetsvakiridzo pane iyo interface pakati pezviviri izvi kuburikidza neakasiyana hunyanzvi nzira. Parizvino, pane kunyanya nzira mbiri dzekuvandudza dambudziko rekubatanidza pakati pedhaimondi neCu matrix: (1) Surface modification treatment ye diamond; (2) Alloying kurapwa kwemhangura matrix.

Kugadziridza dhiyabhorosi dhiyagiramu: (a) Yakananga plating pamusoro pedhaimani; (b) Matrix alloying

(1) Kugadziriswa kwepamusoro kwedhaimani

Kuisa zvinhu zvinoshanda seMo, Ti, W uye Cr pamusoro pechikamu chekusimbisa chikamu chinogona kuvandudza hunhu hwemadhaimani, nekudaro ichiwedzera kupisa kwayo. Sintering inogona kugonesa zvinhu zviri pamusoro kuti zvibatane nekabhoni pamusoro pehupfu hwedhaimani kuumba carbide transition layer. Izvi zvinogonesa mamiriro ekunyorova pakati pedhaimondi nesimbi, uye kupfeka kunogona kudzivirira chimiro chedhaimondi kubva kuchinje pakupisa kwakanyanya.

(2) Kubatanidzwa kwemhangura matrix

Pamberi pekugadzirwa kwezvinhu zvinosanganiswa, pre-alloying kurapwa kunoitwa pasimbi yemhangura, iyo inogona kuburitsa zvinhu zvakaumbwa zvine kazhinji yakakwirira yekupisa conductivity. Doping inoshanda mumhangura matrix haingogone chete kudzikisa kunyorova Angle pakati pedhaimani nemhangura, asi zvakare kugadzira carbide layer iyo yakasimba soluble mumhangura matrix padiamond / Cu interface mushure mekuita. Neiyi nzira, mazhinji emagapu aripo pane iyo material interface anogadziridzwa uye akazadzwa, nekudaro anovandudza thermal conductivity.

04 Mhedziso

Zvakajairika kurongedza zvinhu zvinodonha mukudzora kupisa kubva kune epamberi machipisi. Dia/Cu macomposites, ane tunable CTE uye Ultrahigh thermal conductivity, inomiririra inoshandura mhinduro kune inotevera-chizvarwa zvemagetsi.

Sebhizimusi repamusoro-soro rinobatanidza indasitiri nekutengeserana, XKH inotarisa pakutsvagisa nekusimudzira uye kugadzirwa kwedhaimondi/mhangura macomposites uye yakakwirira-inoshanda simbi matrix macomposites akadai seSiC/Al neGr/Cu, ichipa hutsva hwekutonga kwemafuta ekutonga neanopisa conductivity inopfuura 900W/(m·K) yeminda yemagetsi epaketi yemagetsi.

XKH's Diamond yemhangura yakapfeka laminate inoumbwa zvinhu:

Nguva yekutumira: May-12-2025