SPC (Statistical process Control) chishandiso chakakosha mukugadzira wafer, chinoshandiswa kutarisa, kutonga, uye kugadzirisa kugadzikana kwematanho akasiyana mukugadzira.

1. Pfupiso yeSPC System

SPC inzira inoshandisa statistical matekiniki kutarisa uye kutonga maitiro ekugadzira. Basa rayo rekutanga ndere kuona kusanzwisisika mukuita kwekugadzira nekuunganidza uye kuongorora data-chaiyo-nguva, kubatsira mainjiniya kugadzirisa nenguva uye sarudzo. Chinangwa cheSPC ndechekuderedza kusiyanisa mukuita kwekugadzira, kuve nechokwadi kuti mhando yechigadzirwa inoramba yakagadzikana uye inosangana nezvakatemwa.

SPC inoshandiswa mukuita etching ku:

Monitor yakakosha michina parameter (semuenzaniso, etch rate, RF simba, kamuri yekumanikidza, tembiricha, nezvimwewo)

Ongorora zvakakosha zviratidzi zvemhando yechigadzirwa (semuenzaniso, mutsara, kudzika kwe etch, kushata, nezvimwewo)

Nekutarisa aya ma paramita, mainjiniya anogona kuona mafambiro anoratidza kuparara kwemidziyo kana kutsauka munzira yekugadzira, nekudaro kudzikisa mitengo yezvikara.

2. Zvikamu zvakakosha zveSPC System

Iyo SPC sisitimu inoumbwa akati wandei akakosha mamodule:

Data Kuunganidza Module: Inounganidza chaiyo-nguva data kubva kumidziyo uye nzira inoyerera (semuenzaniso, kuburikidza neFDC, EES masisitimu) uye inorekodha yakakosha paramita uye mhedzisiro yekugadzira.

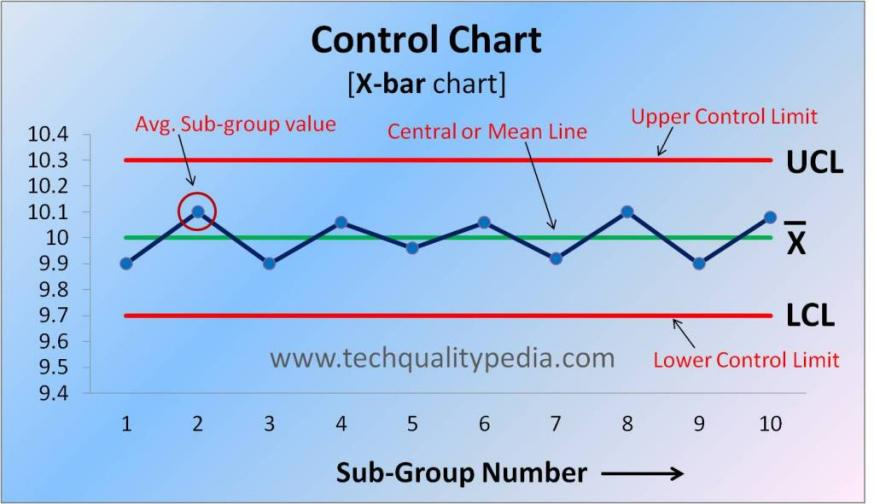

Kudzora Chati Module: Inoshandisa nhamba yekudzora machati (semuenzaniso, X-Bar chart, R chart, Cp/Cpk chart) kuona kugadzikana kwemaitiro uye kubatsira kuona kana maitiro ari kutonga.

Alarm System: Inokonzeresa maaramu kana yakakosha paramita ichidarika miganhu yekudzora kana kuratidza shanduko yemaitiro, zvichiita kuti mainjiniya atore matanho.

Kuongorora uye Kurevera Module: Inoongorora iyo midzi inokonzeresa anomalies yakavakirwa paSPC machati uye inogara ichigadzira mishumo yekushanda kwemaitiro uye michina.

3. Tsanangudzo Yakadzama yeKudzora Machati muSPC

Kudzora machati ndechimwe chezvishandiso zvinonyanya kushandiswa muSPC, zvichibatsira kusiyanisa pakati pe "zvakajairwa kusiyanisa" (kunokonzerwa nekusiyana kwemaitiro echisikigo) uye "kusiyana kusingawanzo" (kunokonzerwa nekutadza kwemidziyo kana kutsauka kwemaitiro). Common control charts dzinosanganisira:

X-Bar uye R Machati: Anoshandiswa kutarisa zvinoreva uye renji mukati mekugadzira mabheti kuona kana maitiro akagadzikana.

Cp uye Cpk Indices: Inoshandiswa kuyera kugona kwekuita, kureva, kana iyo nzira inobuda inogona kuenderana nezvinodiwa. Cp inoyera kugona kugona, nepo Cpk ichifunga kutsauka kwenzvimbo yepakati kubva kune yakatarwa miganho.

Semuenzaniso, mukuita etching, unogona kutarisa ma parameter senge etch rate uye kushata kwepamusoro. Kana iyo etch rate yechimwe chimedu chemidziyo ichidarika muganho wekutonga, unogona kushandisa machati ekudzora kuona kana ichi chiri mutsauko wechisikigo kana chiratidzo chekusashanda kwemidziyo.

4. Kushandiswa kweSPC muEtching Equipment

Mukuita etching, kudzora ma paramita emidziyo kwakakosha, uye SPC inobatsira kuvandudza kugadzikana kwemaitiro nenzira dzinotevera:

Equipment Condition Monitoring: Masisitimu akaita seFDC anounganidza-chaiyo-nguva data pane akakosha paramita etching michina (semuenzaniso, RF simba, gasi kuyerera) uye sanganisa iyi data neSPC kutonga machati kuona zvingangoitika zvemidziyo. Semuenzaniso, kana iwe ukaona kuti iyo RF simba pane yekudzora chati iri kutsauka zvishoma nezvishoma kubva pamutengo wakatarwa, unogona kutora matanho ekutanga kugadzirisa kana kugadzirisa kudzivirira kukanganisa kunaka kwechigadzirwa.

Kutariswa Kwemhando Yechigadzirwa: Unogona zvakare kuisa akakosha emhando yechigadzirwa paramita (semuenzaniso, kudzika kwe etch, mutsara) muSPC system yekutarisa kugadzikana kwavo. Kana zvimwe zviratidzo zvechigadzirwa zvakakosha zvishoma nezvishoma zvichitsauka kubva kune zvakanangwa kukosha, iyo SPC sisitimu inoburitsa alarm, zvichiratidza kuti kugadzirisa kwemaitiro kunodiwa.

Preventive Maintenance (PM): SPC inogona kubatsira kukwenenzvera yekudzivirira kuchengetedza kutenderera kwemidziyo. Nekuongorora data renguva refu pamusoro pekushanda kwemidziyo uye maitiro ekugadzirisa, unogona kuona iyo yakakwana nguva yekugadzirisa michina. Semuenzaniso, nekutarisa RF simba uye ESC hupenyu hurefu, unogona kuona kana kuchenesa kana chikamu chinotsiviwa chinodiwa, kudzikisa mitengo yekutadza kwemidziyo uye kuderera kwekugadzira.

5. Daily Kushandisa Mazano eSPC System

Paunenge uchishandisa iyo SPC system mukushanda kwemazuva ese, matanho anotevera anogona kuteverwa:

Define Key Control Parameters (KPI): Ziva iyo inonyanya kukosha paramita mukuita kwekugadzira uye uisanganise muSPC yekutarisa. Aya ma paramita anofanirwa kuve ane hukama nemhando yechigadzirwa uye mashandiro emidziyo.

Seta Kudzora Miganho uye Alarm Limits: Zvichienderana nenhoroondo yedata uye maitiro ezvinoda, isa inonzwisisika yekudzora miganho uye maaramu miganhu yeparameter yega yega. Kudzora miganho inowanzoiswa pa ± 3σ (yakajairwa kutsauka), nepo alarm miganho yakavakirwa pane chaiwo mamiriro ekuita uye zvishandiso.

Kuenderera Kuongorora uye Kuongorora: Nguva dzose ongorora SPC kutonga machati kuti uongorore data mafambiro uye kusiyana. Kana mamwe ma paramita akadarika miganhu yekudzora, chiito chekukurumidza chinodiwa, sekugadzirisa ma paramita emidziyo kana kuita kugadzirisa kwemidziyo.

Abnormality Kubata uye Root Cause Ongororo: Kana kusagadzikana kukaitika, iyo SPC system inonyora ruzivo rwakadzama nezve chiitiko. Iwe unofanirwa kugadzirisa uye kuongorora chikonzero cheiyo abnormality zvichienderana neruzivo urwu. Zvinowanzogoneka kusanganisa data kubva kuFDC masisitimu, EES masisitimu, nezvimwewo, kuongorora kuti nyaya yacho inokonzerwa nekutadza kwemidziyo, kutsauka kwemaitiro, kana zvekunze kwezvakatipoteredza.

Kuenderera mberi Kuvandudza: Uchishandisa iyo nhoroondo data yakanyorwa neSPC system, tsvaga isina kusimba mukuita uye kurudzira zvirongwa zvekuvandudza. Semuyenzaniso, mukuita etching, ongorora maitiro eESC lifespan uye nzira dzekuchenesa pamatanho ekugadzirisa midziyo uye ramba uchikwenenzvera maparamita ekushandisa.

6. Practical Application Case

Semuenzaniso unoshanda, ngatiti iwe uri mutoro weiyo etching E-MAX, uye kamuri cathode iri kusangana nekupfeka nguva isati yakwana, zvichikonzera kuwedzera kweD0 (BARC defect) kukosha. Nekutarisa iyo RF simba uye etch chiyero kuburikidza neSPC sisitimu, iwe unoona maitiro apo aya maparamita anotsauka zvishoma nezvishoma kubva kune awo akaseta hunhu. Mushure mekunge alarm yeSPC yatanga, unosanganisa data kubva kuFDC system uye woona kuti nyaya yacho inokonzerwa nekusagadzikana kwekudzora tembiricha mukati mekamuri. Iwe wobva washandisa nzira nyowani dzekuchenesa uye nzira dzekugadzirisa, pakupedzisira uchidzikisa kukosha kweD0 kubva pa4.3 kusvika 2.4, nekudaro uchivandudza kunaka kwechigadzirwa.

7.Mu XINKEHUI unogona kuwana.

PaXINKEHUI, unogona kuwana yakanakisa wafer, ingave silicon wafer kana SiC wafer. Isu tine hunyanzvi mukuunza epamusoro-mhando wafers kune akasiyana maindasitiri, tichitarisa pakurongeka uye kuita.

(Silicone wafer)

Yedu silicon wafers akagadzirwa nekuchena kwepamusoro uye kufanana, kuve nechokwadi chemagetsi emhando yepamusoro kune ako semiconductor zvaunoda.

Kune mamwe maapplication ari kudiwa, yedu SiC wafers inopa yakasarudzika yekupisa conductivity uye yakakwirira simba kushanda zvakanaka, yakanakira magetsi emagetsi uye yakakwirira-tembiricha nharaunda.

(SiC wafer)

NeXINKEHUI, unowana tekinoroji yekucheka-kumucheto uye tsigiro yakavimbika, inovimbisa zvitete zvinosangana nepamusoro-soro indasitiri zviyero. Sarudza isu nekuda kwekunaka kwako kwechingwa!

Nguva yekutumira: Oct-16-2024