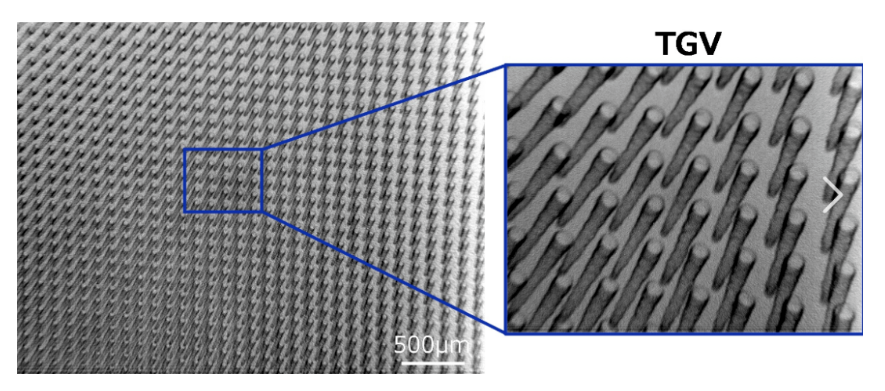

Chii chinonzi TGV?

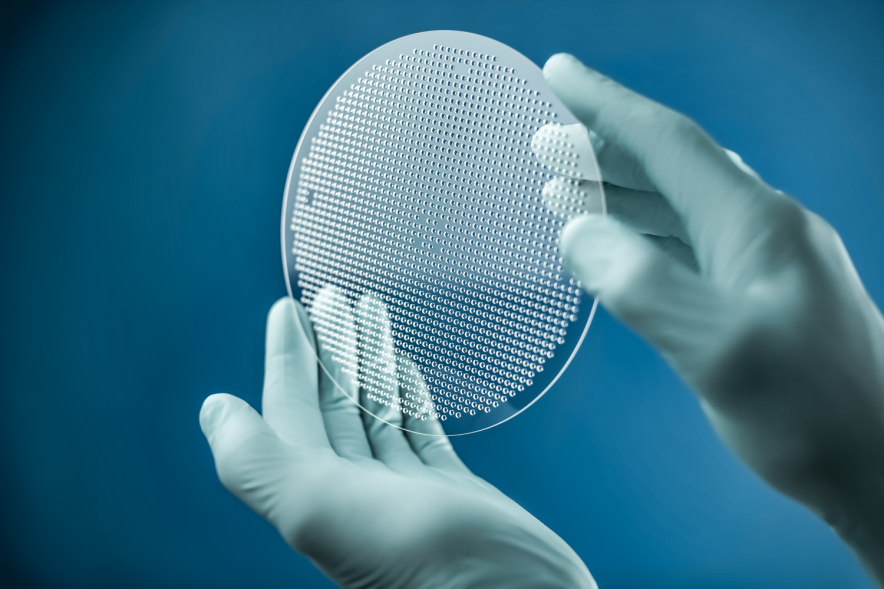

TGV, (Kuburikidza neGirazi kuburikidza), teknolojia yekugadzira kuburikidza-makomba pane girasi substrate, Mumashoko akajeka, TGV chivakwa chepamusoro-soro chinoputira, chinozadza uye chinobatanidza kumusoro uye pasi girasi kuti ivake masangano akabatanidzwa pagirazi pasi. Iyi tekinoroji inoonekwa seyakakosha tekinoroji yechizvarwa chinotevera che3D kurongedza.

Ndeapi maitiro eTGV?

1. Mamiriro: TGV inofambisa yakadzikama inopinda nepaburi rakagadzirwa pane substrate yegirazi. Nekuisa conductive simbi layer pamadziro epore, epamusoro neakadzika maseru emagetsi masaini akabatana.

2. Manufacturing process: TGV kugadzira kunosanganisira substrate pretreatment, gomba kugadzira, metal layer deposition, gomba kuzadza uye flattening matanho. Yakajairika nzira dzekugadzira makemikari etching, laser drilling, electroplating uye zvichingodaro.

3. Mabhenefiti ekushandisa: Kuenzaniswa nesimbi yechinyakare kuburikidza negomba, TGV ine zvakanakira saizi diki, yakakwirira wiring density, nani kupisa kupisa kuita uye zvichingodaro. Inoshandiswa zvakanyanya mumakroelectronics, optoelectronics, MEMS uye mamwe minda yehupamhi-density yekubatanidza.

4. Mafambiro ebudiriro: Nekuvandudzwa kwezvigadzirwa zvemagetsi kuenda kuminiaturization uye kubatanidzwa kwepamusoro, tekinoroji yeTGV iri kugamuchira zvakanyanya uye zvakanyanya kutariswa uye kushandisa. Mune ramangwana, maitiro ayo ekugadzira acharamba achigadziriswa, uye saizi yayo uye kuita kwayo kucharamba kuchivandudza.

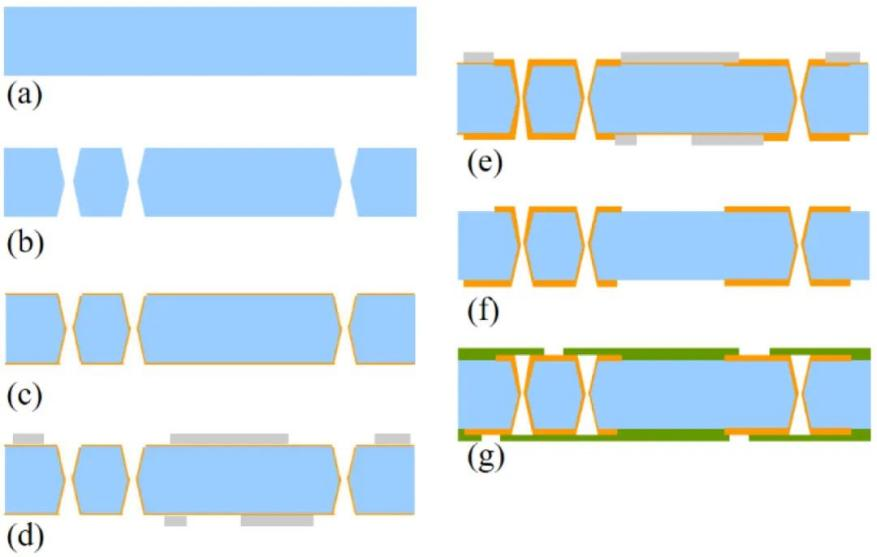

Chii chinonzi TGV maitiro:

1. Girazi substrate kugadzirira (a) : Gadzirira girasi substrate pakutanga kuti uone kuti nzvimbo yaro yakatsetseka uye yakachena.

2. Girazi drilling (b) : Laser inoshandiswa kuumba gomba rekupinda mugirazi substrate. Chimiro chegomba chinowanzo conical, uye mushure mekurapwa kwelaser kune rimwe divi, inopindurwa uye kugadziridzwa kune rimwe divi.

3. Hole wall metallization (c) : Metallization inoitwa pamadziro egomba, kazhinji kuburikidza nePVD, CVD uye mamwe maitiro ekugadzira conductive simbi seed layer pamadziro egomba, seTi / Cu, Cr / Cu, nezvimwe.

4. Lithography (d) : Pamusoro pegirazi substrate yakafukidzwa ne photoresist uye photopatterned. Ratidza zvikamu zvisingade kuputirwa, kuitira kuti chete zvikamu zvinoda plating zviburitswe.

5. Hole filling (e) : Electroplating mhangura yekuzadza girazi kuburikidza nemakomba kuti iite yakakwana conductive nzira. Zvinowanzodiwa kuti gomba rizadzwe zvachose pasina maburi. Ziva kuti iyo Cu iri mudhayagiramu haina kuzara vanhu.

6. Flat surface ye substrate (f) : Mamwe maitiro eTGV achagadzirisa nzvimbo yegirasi yakazadza substrate kuti ive nechokwadi chokuti nzvimbo ye substrate yakanyorova, iyo inobatsira kune matanho anotevera ekugadzirisa.

7.Protective layer uye terminal connection (g) : Mushonga wekudzivirira (wakadai se polyimide) unoumbwa pamusoro pegirasi substrate.

Muchidimbu, nhanho yega yega yeTGV maitiro yakakosha uye inoda kunyatso kudzora uye kugadzirisa. Isu parizvino tinopa TGV girazi kuburikidza negomba tekinoroji kana zvichidikanwa. Ndapota inzwa wakasununguka kutibata nesu!

(Ruzivo rwuri pamusoro rwunobva paInternet, censoring)

Nguva yekutumira: Jun-25-2024