Yakakwirira-kuchena silicon carbide (SiC) ceramics yakabuda seyakanakira zvinhu zvezvinhu zvakakosha mu semiconductor, aerospace, uye maindasitiri emakemikari nekuda kwekusiyana kwavo kwekupisa kwekushisa, kugadzikana kwemakemikari, uye simba remuchina. Nekuwedzera kuri kuda kwezvishandiso zvepamusoro-soro, zvakaderera-kusvibiswa kweceramic zvishandiso, kuvandudzwa kwehunyanzvi uye scalable kugadzirira matekinoroji epamusoro-kuchena SiC ceramics kwave kutsvaga kwepasirese kutarisisa. Iri bepa rinonyatsoongorora nzira dzemazuva ano dzekugadzirira kwepamusoro-kuchena SiC ceramics, kusanganisira recrystallization sintering, pressureless sintering (PS), hot pressing (HP), spark plasma sintering (SPS), uye additive kugadzira (AM), nechisimbiso pakukurukura nzira dze sintering, zvakakosha paramita, zvinhu zvenyama, uye matambudziko aripo ega rega rega.

Iko kushandiswa kweSiC ceramics mumauto uye engineering minda

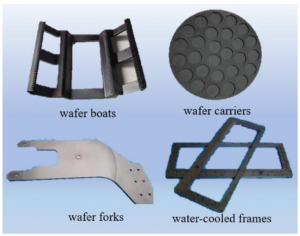

Parizvino, yakakwirira-kuchena SiC ceramic zvikamu zvinoshandiswa zvakanyanya musilicon wafer kugadzira michina, kutora chikamu mumasikisi maitiro senge oxidation, lithography, etching, uye ion implantation. Nekufambira mberi kwewafer tekinoroji, kuwedzera saizi yewafer kwave kuita kwakakosha. Ikozvino mainstream wafer size i300 mm, kuwana chiyero chakanaka pakati pemutengo uye kugona kwekugadzira. Nekudaro, ichitungamirwa neMutemo waMoore, kugadzirwa kwakawanda kwe450 mm wafers kwatove pachirongwa. Mawaferi akakura anowanzo kuda simba repamusoro rekuramba kurwa uye deformation, zvichienderera mberi nekufambisa kudiwa kuri kukura kwehukuru-hukuru, yakakwirira-simba, yakakwirira-kuchena SiC ceramic zvikamu. Mumakore achangopfuura, kugadzirwa kwekuwedzera (3D printing), sekukurumidza prototyping tekinoroji isingade mold, yakaratidza kugona kukuru mukugadzirwa kwezvikamu zvakaoma-zvakaumbwa zveSiC ceramic zvikamu nekuda kwekuvakwa kwayo-ne-layer uye kugona kuchinjika kwekugadzira, kukwezva kutarisisa kwakapararira.

Iri bepa richaongorora zvine hurongwa shanu dzinomiririra nzira dzekugadzirira dzepamusoro-kuchena SiC ceramics-recrystallization sintering, pressureless sintering, hot pressing, spark plasma sintering, uye additive kugadzira-ichitarisa maitiro avo ekupisa, maitiro ekugadzirisa maitiro, maitiro ekuita zvinhu, uye tarisiro yekushandiswa kwemaindasitiri.

Yakakwirira-kuchena silicon carbide mbishi zvinhu zvinodiwa

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) ndeyepamusoro-kuchena SiC zvinhu zvakagadzirirwa pasina sintering aids pane yakakwirira tembiricha ye2100-2500 ° C. Kubva Fredriksson akatanga kuwana chiitiko chekristalllization mukupera kwezana ramakore rechi 19, RSiC yakawana kutarisisa nekuda kwemiganhu yayo yezviyo yakachena uye kusavapo kwezvikamu zvegirazi uye tsvina. Pakupisa kwakanyanya, SiC inoratidzira yakakwira mhute kumanikidza, uye yayo sintering maitiro anonyanya kusanganisira evaporation-condensation process: mitsetse yakanaka inoputika uye inodzoreredza pameso ezviyo zvakakura, kukurudzira kukura kwemutsipa uye kubatana kwakananga pakati pezviyo, nekudaro kunowedzera simba rezvinhu.

Muna 1990, Kriegesmann akagadzira RSiC ine hushamwari hwe79.1% achishandisa slip casting pa2200 ° C, nechikamu-chepakati chinoratidza microstructure inoumbwa nezviyo zvakakora uye pores. Zvadaro, Yi et al. akashandisa gel casting kugadzira miviri yakasvibirira uye yakanyura pa2450 ° C, ichiwana RSiC ceramics ine hulk density ye2.53 g/cm³ uye kuchinjika simba kwe55.4 MPa.

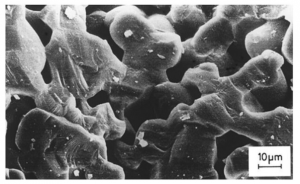

Iyo SEM yakatsemuka pamusoro peRSiC

Kana ichienzaniswa neDense SiC, RSiC ine density yakaderera (inenge 2.5 g/cm³) uye inenge 20% yakavhurika porosity, ichidzikamisa kuita kwayo mukusimba-kwesimba maapplication. Naizvozvo, kuvandudza density uye michina zvimiro zveRSiC yave yakakosha yekutarisisa. Sung et al. inokurudzirwa kupinza silicon yakanyungudutswa mucarbon / β-SiC yakasanganiswa compacts uye recrystallizing pa 2200 ° C, inobudirira kugadzira network yakaumbwa inoumbwa ne α-SiC coarse tsanga. Iyo RSiC yakazokonzeresa yakawana density ye2.7 g/cm³ uye kuchinjika kwesimba re134 MPa, kuchengetedza yakanakisa mechaniki kugadzikana pakupisa kwakanyanya.

Kuti uwedzere kuwedzera kuwanda, Guo et al. akashandisa polymer infiltration uye pyrolysis (PIP) tekinoroji yekurapa kwakawanda kweRSiC. Uchishandisa PCS/xylene mhinduro uye SiC/PCS/xylene slurries sevanopinda mukati, mushure meiyo 3-6 PIP kutenderera, density yeRSiC yakavandudzwa zvakanyanya (kusvika 2.90 g/cm³), pamwe chete nesimba rayo rekuchinja. Pamusoro pezvo, vakaronga cyclic zano rekubatanidza PIP uye recrystallization: pyrolysis pa1400 ° C inoteverwa nerecrystallization pa2400 ° C, zvinobudirira kuchenesa particle blockages uye kuderedza porosity. Iyo yekupedzisira RSiC zvinhu yakawana density ye2.99 g/cm³ uye kuchinjika kwesimba re162.3 MPa, ichiratidza kuita kwakadzama kwakazara.

SEM mifananidzo ye microstructure evolution ye polished RSiC mushure me polymer impregnation uye pyrolysis (PIP) -recrystallization cycles: Initial RSiC (A), mushure mekutanga PIP-recrystallization cycle (B), uye mushure mechitatu chetatu (C)

II. Pressureless Sintering

Pressureless-sintered silicon carbide (SiC) ceramics inowanzogadzirwa nepamusoro-kuchena, ultrafine SiC poda seyakabikwa, ine zvidiki zvekubatsira sintering yakawedzerwa, uye sinter muinert mhepo kana vacuum pa1800-2150 ° C. Iyi nzira yakakodzera kugadzira yakakura-saizi uye yakaoma-yakaomeswa-yakaomeswa ceramic zvikamu. Nekudaro, sezvo SiC ichinyanya kusungirirwa, yayo yekuzviparadzira coefficient yakaderera zvakanyanya, zvichiita kuti densification iome pasina sintering aids.

Zvichienderana nemuchina wekunyunguduka, kusadzvanya kusingadzoreki kunogona kukamurwa kuita mapoka maviri: isina kudzvanywa mvura-chikamu sintering (PLS-SiC) uye isina kudzvanywa solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC inowanzo sintered pazasi 2000 ° C nekuwedzera ingangoita 10 wt.% ye eutectic sintering aids (yakadai seAl₂O₃, CaO, MgO, TiO₂, uye isingawanzo-yepasi oxides RE₂O₃) kuumba chikamu chemvura, kusimudzira dens particle uye kutamisa kumashure. Maitiro aya akakodzera maindasitiri-giredhi SiC ceramics, asi hapasati paine mishumo yekuchena-kuchena kweSiC yakawanikwa kuburikidza nemvura-chikamu sintering.

1.2 PSS-SiC (Solid-State Sintering)

PSS-SiC inosanganisira solid-state densification patembiricha iri pamusoro pe2000°C ine ingangoita 1 wt.% yezvinowedzera. Ichi chiitiko chinotsamira zvakanyanya pakupararira kweatomu uye kurongeka kwezviyo kunotungamirwa nekupisa kwakanyanya kuderedza simba repamusoro uye kuwana densification. Iyo BC (boron-carbon) system ndeye yakajairika yekuwedzera musanganiswa, iyo inogona kuderedza zviyo muganhu simba uye kubvisa SiO₂ kubva kuSiC pamusoro. Nekudaro, zvechinyakare BC zvinowedzera zvinowanzounza tsvina yakasara, ichidzikisa kuchena kweSiC.

Nokudzora zvinyorwa zvekuwedzera (B 0.4 wt.%, C 1.8 wt.%) uye sintering pa 2150 ° C kwemaawa 0.5, high-purity SiC ceramics ine kuchena kwe99.6 wt.% uye hukama hwehukama hwe98.4% hwakawanikwa. Iyo microstructure yakaratidza columnar zviyo (zvimwe zvinodarika 450 µm pakureba), zviine pores madiki pamiganhu yezviyo uye graphite particles mukati mezviyo. Maceramics airatidza kuchinjika kwesimba re443 ± 27 MPa, elastic modulus ye420 ± 1 GPa, uye kupisa kwekuwedzera coefficient ye3.84 × 10⁻⁶ K⁻¹ muhuwandu hwekushisa kwekamuri kusvika 600 ° C, ichiratidza kuita kwakanakisa kwese.

Microstructure yePSS-SiC: (A) SEM mufananidzo mushure mekupenya uye NaOH etching; (BD) BSD mifananidzo mushure mekupenya uye etching

III. Hot Pressing Sintering

Kupisa kudzvanya (HP) sintering inzira ye densification iyo panguva imwe chete inoshandisa kupisa uye uniaxial kudzvanywa kune hupfu zvinhu pasi pepamusoro-tembiricha uye yakakwirira-kudzvanywa mamiriro. Kudzvinyirirwa kwakanyanya kunodzivirira kuumbwa kwepore uye kumisa kukura kwezviyo, nepo tembiricha yakakwira inosimudzira kusanganiswa kwezviyo uye kuumbwa kwezvimiro zvakaomesesa, pakupedzisira ichigadzira yakakwirira-density, yakakwirira-kuchena SiC ceramics. Nekuda kwehunhu hwekutsikirira, kuita uku kunowanzo kukonzeresa anisotropy yezviyo, inokanganisa michina uye kupfeka zvinhu.

Pure SiC Ceramics yakaoma kuomesa pasina zvinowedzera, inoda ultrahigh-pressure sintering. Nadeau et al. kugadzirira zvakakwana dense SiC pasina additives pa 2500 ° C uye 5000 MPa; Zuva et al. yakawana β-SiC zvinhu zvakawanda zvine Vickers kuoma kwekusvika 41.5 GPa pa25 GPa uye 1400 ° C. Kushandisa 4 GPa pressure, SiC ceramics ine hama densities inoita 98% uye 99%, kuomarara kwe35 GPa, uye elastic modulus ye450 GPa zvakagadzirirwa pa1500 ° C uye 1900 ° C, zvichiteerana. Sintering micron-sized SiC powder pa5 GPa uye 1500 ° C yakapa ceramics ine kuoma kwe31.3 GPa uye hukama hwepakati hwe98.4%.

Kunyangwe izvi mhedzisiro zvichiratidza kuti ultrahigh pressure inogona kuwana yekuwedzera-yemahara densification, kuoma uye kudhura kwakanyanya kwemidziyo inodiwa inodzikamisa maindasitiri ekushandisa. Naizvozvo, mukugadzirira kunoshanda, kutsvaga zvinowedzerwa kana poda granulation zvinowanzo shandiswa kuwedzera sintering kutyaira simba.

Nekuwedzera 4 wt.% phenolic resin sekuwedzera uye sintering pa2350 ° C uye 50 MPa, SiC ceramics ine densification rate ye92% uye kuchena kwe99.998% yakawanikwa. Kushandisa yakaderera kuwedzera mari (boric acid uye D-fructose) uye sintering pa2050 ° C uye 40 MPa, yakakwirira-kuchena SiC ine hama density> 99.5% uye yakasara B zvinyorwa chete 556 ppm yakagadzirirwa. Mifananidzo yeSEM yakaratidza kuti, zvichienzaniswa nemasampuli asina kudzvanywa-sintered, masampuli anopisa ane zviyo zvidiki, mashoma pores, uye yakakwirira density. Simba rekuchinja raive 453.7 ± 44.9 MPa, uye elastic modulus yakasvika 444.3 ± 1.1 GPa.

Nekuwedzera nguva yekubata pa 1900 ° C, saizi yezviyo yakawedzera kubva ku1.5 μm kusvika 1.8 μm, uye kupisa kwekushisa kwakagadziridzwa kubva ku155 kusvika 167 W · m⁻¹·K⁻¹, uyewo kuwedzera plasma corrosion resistance.

Pasi pemamiriro e1850 ° C uye 30 MPa, kupisa kupisa uye kukurumidza kupisa kudzvanya kwe granulated uye annealed SiC poda yakabereka zvizere dense β-SiC ceramics pasina zvimwe zvinowedzera, ine density ye 3.2 g/cm³ uye sintering tembiricha 150-200 ° C yakaderera pane tsika dzechinyakare. Maceramics airatidza kuomarara kwe2729 GPa, kuomarara kwekutsemuka kwe5.25–5.30 MPa·m^1/2, uye yakanakisa kukambaira (zvinokambaira zvinosvika 9.9 × 10⁻¹⁰ s⁻¹ uye 3.8 × 10⁻⁻⁹0 ° 10⁻⁻⁹0 ° C1⁻⁻⁹0 ° C / 10 ° 4 ° s / C1 ° 0 s / 10 ° 10 ° s / 1 / 10 ° 0 s 10 ° 0 s 10 ° na C1 / 10 ° 4 ° 0 s 1 / 10 10 ° na C1 / 10 ° 4 ° 0 0 10 ° 0 0 5 ° 0 0 10 ° 0 s 10 ° 0 0 5 ° 0 0 s 4 ° 0 1 s 100 MPa).

(A) SEM mufananidzo wenzvimbo yakakwenenzverwa; (B) SEM mufananidzo wekuputsika kwepamusoro; (C, D) BSD mufananidzo wenzvimbo yakakwenenzverwa

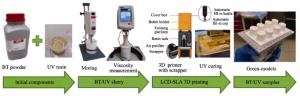

Mukutsvaga kwe 3D kudhinda kwepiezoelectric ceramics, ceramic slurry, sechinhu chikuru chinofurira kuumbwa nekuita, chave chinhu chakakosha kutariswa mukati mekunze kwenyika. Zvidzidzo zvazvino zvinowanzo ratidza kuti maparamendi akadai sehupfu chidimbu saizi, slurry viscosity, uye yakasimba zvemukati zvinokanganisa zvakanyanya kuumbwa kwemhando uye piezoelectric zvimiro zvechigadzirwa chekupedzisira.

Tsvagiridzo yakawana kuti ceramic slurries yakagadzirirwa kushandisa micron-, submicron-, uye nano-saizi barium titanate poda inoratidza misiyano yakakura mune sterolithography (semuenzaniso, LCD-SLA) maitiro. Sezvo particle size inodzikira, slurry viscosity inowedzera zvakanyanya, ne nano-saizi hupfu huchigadzira slurries ane viscosity inosvika mabhiriyoni emamPa·s. Slurries ine micron-saizi poda inongoita delamination uye peeling panguva yekudhinda, nepo submicron uye nano-saizi poda inoratidza yakagadzikana kuumba maitiro. Mushure mekupisa-kupisa kwepamusoro-soro, izvo zvakazoitika zveceramic samples zvakawana density ye5.44 g/cm³, piezoelectric coefficient (d₃₃) yeanenge 200 pC/N, uye yakaderera kurasikirwa zvinhu, ichiratidza yakanakisa electromechanical mhinduro zvivakwa.

Uyezve, mune micro-stereolithography maitiro, kugadzirisa zvakasimba zvinyorwa zvePZT-mhando slurries (eg, 75 wt.%) yakabereka miviri yakasvibiswa ine density ye 7.35 g / cm³, ichiwana piezoelectric constant inosvika 600 pC/N pasi peminda yemagetsi. Tsvagiridzo pamusoro peiyo micro-scale deformation muripo yakavandudza kuumbwa kwechokwadi, ichivandudza geometric chaiyo nekusvika 80%.

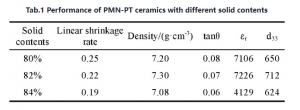

Imwe ongororo paPMN-PT piezoelectric ceramics yakaratidza kuti yakasimba yemukati inopesvedzera chimiro checeramic uye zvivakwa zvemagetsi. Pa80 wt.% yakasimba yemukati, byproducts yakaonekwa zviri nyore mumakeramiki; sezvo yakasimba yemukati yakawedzera kusvika 82 wt.% uye pamusoro, byproducts zvishoma nezvishoma zvakanyangarika, uye chimiro checeramic chakava chakachena, nekuita kwakagadziridzwa zvakanyanya. Pa 82 wt.%, ma ceramics airatidza optimal emagetsi zvivakwa: piezoelectric constant ye 730 pC/N, hama mvumo ye7226, uye dielectric kurasikirwa kwe0.07 chete.

Muchidimbu, saizi yechikamu, yakasimba yemukati, uye rheological zvimiro zveceramic slurries hazvingokanganisa kugadzikana uye kurongeka kwemaitiro ekudhinda, asiwo zvakanangana nekuita density uye piezoelectric mhinduro yemitumbi yakanyungudutswa, ichivaita maparamita akakosha ekuwana yakakwira-performance 3D-yakadhindwa piezoelectric ceramics.

Iyo huru maitiro eLCD-SLA 3D kudhindwa kweBT/UV samples

Izvo zvimiro zvePMN-PT ceramics ine akasiyana akasimba emukati

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) tekinoroji yepamberi yekuisa tekinoroji inoshandisa pulsed ikozvino uye mechanical pressure panguva imwe chete inoiswa kune hupfu kuti uwane nekukurumidza densification. Muchiitiko ichi, ikozvino inopisa zvakananga mold uye hupfu, ichiita Joule kupisa uye plasma, zvichiita kuti sintering ibudirire munguva pfupi (kazhinji mukati memaminitsi e10). Kukurumidza kupisa kunosimudzira kupararira kwepasi, nepo kubuda kwe spark kunobatsira kubvisa adsorbed magasi uye oxide layer kubva paupfu, kuvandudza sintering performance. Iyo electromigration mhedzisiro inokonzereswa nemagetsi emagetsi magineti inowedzerawo kupararira kweatomu.

Kuenzaniswa nekutsikirira kwechinyakare, SPS inoshandisa kudziyisa kwakananga, ichigonesa densification patembiricha yakaderera uku ichinyatso kuvharidzira kukura kwezviyo kuti iwane yakanaka uye yakafanana microstructures. Semuyenzaniso:

- Pasina zvinowedzera, kushandisa pasi SiC poda seyakagadzirwa, sintering pa2100 ° C uye 70 MPa kwemaminetsi makumi matatu yakaburitsa samples ine 98% hama density.

- Sintering pa1700 ° C uye 40 MPa kwemaminetsi gumi yakagadzira cubic SiC ine 98% density uye saizi yezviyo chete 30-50 nm.

- Kushandisa 80 µm granular SiC powder uye sintering pa 1860 ° C uye 50 MPa kwemaminetsi mashanu zvakakonzera kushanda kwepamusoro-soro kweSiC ceramics ne 98.5% hukama hwehukama, Vickers microhardness ye 28.5 GPa, flexural simba re 395 MPa, uye kutyoka ^ 4 / 2 MPa · kuoma.

Microstructural analysis yakaratidza kuti sezvo sintering tembiricha yakawedzera kubva 1600 ° C kusvika 1860 ° C, zvinhu porosity yakaderera zvikuru, kusvika kuzara density panguva yakakwirira tembiricha.

Iyo microstructure yeSiC ceramics yakanyungudutswa pakupisa kwakasiyana: (A) 1600°C, (B) 1700°C, (C) 1790°C uye (D) 1860°C.

V. Additive Manufacturing

Additive kugadzira (AM) ichangobva kuratidza hukuru hwakasimba mukugadzira zvinhu zvakaoma zveceramic nekuda kweiyo layer-by-layer yekuvaka maitiro. Kune SiC ceramics, akawanda AM matekinoroji akagadzirwa, anosanganisira binder jetting (BJ), 3DP, selective laser sintering (SLS), yakananga inki kunyora (DIW), uye stereolithography (SL, DLP). Nekudaro, 3DP uye DIW ine yakaderera chaiyo, nepo SLS inowanzokonzera kushushikana kwekupisa uye kutsemuka. Kusiyana neizvi, BJ uye SL inopa mabhenefiti makuru mukugadzira yakakwira-kuchena, yakakwirira-chaiyo yakaoma yakaoma ceramics.

- Binder Jetting (BJ)

BJ tekinoroji inosanganisira layer-by-layer spraying yebinder kune bond poda, inoteverwa nekubvisa uye sintering kuti uwane yekupedzisira ceramic chigadzirwa. Kubatanidza BJ nemakemikari vapor infiltration (CVI), yakakwirira-kuchena, yakazara crystalline SiC ceramics yakagadzirwa zvakabudirira. Iyo nzira inosanganisira:

① Kugadzira SiC ceramic miviri yakasvibira uchishandisa BJ.

② Densifying kuburikidza neCVI pa1000 ° C uye 200 Torr.

③ Yekupedzisira SiC ceramic yakanga ine density ye2.95 g/cm³, thermal conductivity ye37 W/m·K, uye kuchinjika simba kwe297 MPa.

Schematic diagram yeadhesive jet (BJ) kudhinda. (A) Kombuta-inobatsira dhizaini (CAD) modhi, (B) dhizaini yechirongwa cheBJ musimboti, (C) kudhindwa kweSiC neBJ, (D) densification yeSiC nemakemikari vapor infiltration (CVI)

- Stereolithography (SL)

SL ndeye UV-inorapa-yakavakirwa ceramic yekugadzira tekinoroji ine yakanyanya kurongeka uye yakaoma chimiro chekugadzira. Iyi nzira inoshandisa photosensitive ceramic slurries ine yakakwirira yakasimba yezvinhu uye yakaderera viscosity kuumba 3D zvedongo girini miviri kuburikidza photopolymerization, inoteverwa debinding uye yakakwirira-tembiricha sintering kuwana chokupedzisira chigadzirwa.

Ichishandisa 35 vol.% SiC slurry, yemhando yepamusoro 3D miviri yakasvibira yakagadzirwa pasi pe405 nm UV irradiation uye yakawedzera densified kuburikidza nekupisa kwepolymer pa800 ° C uye kurapwa kwePIP. Mhedzisiro yakaratidza kuti samples dzakagadzirirwa ne35 vol.% slurry dzakawana hushamwari hwe84.8%, kupfuura 30% uye 40% mapoka ekudzora.

Nekuunza lipophilic SiO₂ uye phenolic epoxy resin (PEA) kugadzirisa slurry, kuita kwephotopolymerization kwakagadziridzwa zvinobudirira. Mushure mokupisa pa 1600 ° C ye4 h, pedyo-yakazara kutendeuka kuSiC yakave yakawanikwa, ine okisijeni yekupedzisira ye 0.12% chete, zvichiita kuti nhanho imwe chete yekugadzirwa kwepamusoro-kuchena, yakaoma-yakarongeka SiC ceramics pasina pre-oxidation kana pre-infiltration matanho.

Mufananidzo wekudhinda chimiro uye maitiro ayo ekupisa. Kuonekwa kwemuenzaniso mushure mekuoma pa (A) 25 ° C, pyrolysis pa (B) 1000 ° C, uye sintering pa (C) 1600 ° C.

Nekugadzira photosensitive Si₃N₄ ceramic slurries yesterolithography 3D kudhinda uye kushandisa debinding-presintering uye high-tembiricha kuchembera, Si₃N₄ ceramics ine 93.3% theoretical density, tensile simba re279.8 MPa, uye 3a303. Zvidzidzo zvakawana kuti pasi pemamiriro e45 vol.% yakasimba yezvinhu uye 10 s kuratidzwa nguva, imwe-layer miviri yakasvibira ine IT77-level yekurapa chaiyo inogona kuwanikwa. Kudziisa-kudzika-tembiricha maitiro ane mwero wekudziya we 0.1 °C/min yakabatsira kuburitsa-isina kuputika miviri yakasvibira.

Sintering inhanho yakakosha inokanganisa kuita kwekupedzisira musterolithography. Tsvagiridzo inoratidza kuti kuwedzera sintering aids inogona kunyatso vandudza ceramic density uye michina zvivakwa. Kushandisa CeO₂ sechiyamuro chesimbi uye yemagetsi-inobatsira sintering tekinoroji kugadzirira yakakwira-density Si₃N₄ ceramics, CeO₂ yakawanikwa ichiparadzanisa pamiganhu yezviyo, ichikurudzira zviyo muganhu kutsvedza uye densification. Maceramics akabuda airatidza Vickers kuomarara kweHV10/10 (1347.9 ± 2.4) uye kuomarara kwekutsemuka kwe (6.57 ± 0.07) MPa·m¹/². NeMgO-Y₂O₃ sezvinowedzera, ceramic microstructure homogeneity yakagadziridzwa, ichinyanya kuwedzera kushanda. Payero yakazara doping ye8 wt.%, flexural simba uye thermal conductivity yakasvika 915.54 MPa uye 59.58 W·m⁻¹·K⁻¹, zvichiteerana.

VI. Mhedziso

Muchidimbu, yakakwirira-kuchena silicon carbide (SiC) ceramics, seyakatanhamara engineering ceramic zvinhu, yakaratidza yakafara tarisiro yekushandisa mune semiconductors, aerospace, uye yakanyanyisa-mamiriro emidziyo. Iri bepa rakanyatsoongorora nzira shanu dzekugadzirira dzepamusoro-kuchena SiC ceramics-recrystallization sintering, pressureless sintering, hot pressing, spark plasma sintering, uye additive kugadzira-ine nhaurirano dzakadzama pamusoro pemaitiro avo e densification, key parameter optimization, kuita zvinhu, uye zvakafanira zvakanakira uye zvinogumira.

Zviripachena kuti maitiro akasiyana ega ega ane akasiyana hunhu maererano nekuwana kuchena kwepamusoro, kusimba kwepamusoro, zvimiro zvakaoma, uye kugona kwemaindasitiri. Tekinoroji yekugadzira yekuwedzera, kunyanya, yakaratidza kugona kwakasimba mukugadzira zvinhu zvakaomarara-zvimiro uye zvakagadziridzwa, zvine mabhindauko munzvimbo diki senge sterolithography uye binder jetting, zvichiita kuti ive danho rakakosha rekusimudzira kwepamusoro-kuchena SiC ceramic gadziriro.

Tsvakurudzo yeramangwana pamusoro pekuchena kwepamusoro-kuchena kweSiC ceramic kugadzirira kunoda kuzama zvakadzama, kusimudzira shanduko kubva murabhoritari-mwero kuenda kune hombe, yakavimbika kwazvo mainjiniya maapplication, nekudaro ichipa rubatsiro rwakakosha rwezvinhu zvekugadzira-yekupedzisira michina uye inotevera-chizvarwa ruzivo matekinoroji.

XKH ibhizimusi repamusoro-soro rinonyanya kutsvagisa uye kugadzirwa kwezvinhu zvepamusoro-soro zveceramic. Yakatsaurirwa kupa zvigadziriso zvevatengi muchimiro chepamusoro-kuchena silicon carbide (SiC) ceramics. Iyo kambani ine epamberi tekinoroji yekugadzira zvinhu uye chaiyo kugadzirisa kugona. Bhizinesi rayo rinosanganisira kutsvagisa, kugadzira, kunyatsogadziriswa, uye kurapwa kwepamusoro kwepamusoro-kuchena SiC ceramics, kusangana nezvinoda kuomesesa zvesemiconductor, simba idzva, aerospace uye mamwe minda yepamusoro-inoshanda ceramic zvikamu. Kusimudzira makura sintering maitiro uye ekuwedzera tekinoroji yekugadzira, isu tinogona kupa vatengi sevhisi imwe-yekumira kubva kuzvinhu formula optimization, yakaoma dhizaini dhizaini kune chaiyo kugadzirisa, kuve nechokwadi chekuti zvigadzirwa zvine zvakanakisa zvemuchina zvivakwa, kugadzikana kwemafuta uye kusagadzikana kwekuora.

Nguva yekutumira: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)